When it comes to crafting stunning apparel and unique designs, achieving **professional-quality DTF transfers** has become an essential skill for DIY enthusiasts. This innovative printing technique, known as Direct-to-Film (DTF) printing, combines vibrant colors with durability, making it an attractive option for both personal projects and small businesses. To help you on this creative journey, we will share valuable DTF printing tips and essential techniques that will empower you to produce eye-catching results without the need for expensive commercial equipment. From understanding how to DTF transfers to optimizing your home DTF printing setup, we’re here to guide you every step of the way. Get ready to unlock the secrets that turn your artistic visions into tangible, high-quality fabric prints.

DTF printing, or Direct-to-Film printing, is revolutionizing the way we approach textile customization. Often referred to as a groundbreaking method for producing vibrant and long-lasting designs, this technique allows for intricate artwork to be effectively transferred onto fabric with ease. Whether you’re exploring DIY DTF printing for personal use or looking to enhance your business offerings, mastering DTF transfer techniques can elevate your craft. This guide will focus on the essential aspects of home DTF printing, ensuring that enthusiasts and professionals alike achieve outstanding results with every project. Prepare to delve into the world of high-quality textile printing as we explore the various components that contribute to spectacular DTF transfers.

Understanding the DTF Printing Process

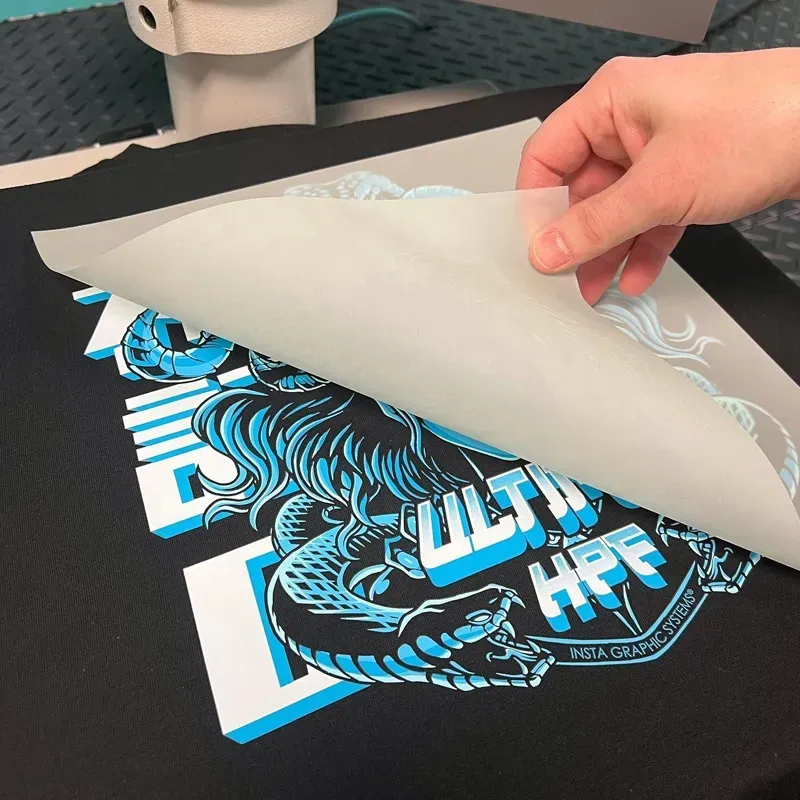

DTF printing, or Direct-to-Film printing, is an innovative technique that allows creatives to transfer intricate designs onto textiles with remarkable precision. The process involves printing designs onto a special film, which is then transferred to fabric using a heat press. This method stands out for its versatility, allowing artists and entrepreneurs alike to produce high-quality prints on a variety of materials. Understanding the intricacies of DTF printing can help you navigate the complexities involved and enhance the quality of your final products.

Moreover, the flexibility of DTF transfers enables users to tap into various creative fields—whether it’s customizing apparel, producing promotional merchandise, or crafting unique home decor. The beauty of DTF printing lies not only in its adaptability but also in its ability to deliver vibrant visuals that truly capture the essence of the original designs. As you delve deeper into DTF printing, familiarizing yourself with various transfer techniques and materials can set the stage for achieving outstanding results.

Frequently Asked Questions

What are the essential DTF printing tips for beginners looking to achieve professional-quality DTF transfers?

To achieve professional-quality DTF transfers, beginners should start with high-quality equipment such as a suitable printer and DTF film. Invest in water-based inks for vibrant colors, and ensure you are using the right adhesive powder. Additionally, mastering the correct heat press settings, including temperature and pressure, is crucial for a successful transfer.

How can I ensure my DIY DTF printing projects yield professional-quality DTF transfers?

For DIY DTF printing, maintain a clean workspace, use compatible materials like DTF film and inks, and follow precise heat press instructions. Regularly practice and test different settings to find the ideal combination for your specific setup, which will help you produce professional-quality DTF transfers.

What are the best DTF transfer techniques for achieving vibrant and long-lasting results?

To achieve vibrant and long-lasting DTF transfers, utilize high-resolution images and quality inks. Ensure you apply even pressure and the correct temperature during the heat transfer process. Additionally, employing a curing process post-transfer will enhance the adherence and durability of your designs.

What types of fabric work best for professional-quality DTF transfers?

Professional-quality DTF transfers can be applied to a variety of fabrics, including cotton, polyester, and blends. Fabric types with a smoother surface tend to yield better results, so selecting the right material is essential for achieving the best transfer quality.

Can I use home DTF printing techniques for commercial purposes?

Yes, home DTF printing techniques can be used for commercial purposes if you maintain high standards in your printing process. Using professional-quality materials and equipment, along with a focus on finishing and post-processing, will ensure that your DTF transfers meet the expectations of a commercial market.

What should I consider when selecting equipment for home DTF printing?

When selecting equipment for home DTF printing, prioritize purchasing a quality printer compatible with DTF technology, high-grade DTF film, and professional-grade inks. Additionally, ensure you have a reliable heat press that allows you to monitor temperature and pressure accurately for consistent, professional-quality DTF transfers.

| Key Point | Details |

|---|---|

| What is DTF Printing? | An innovative approach where designs are printed on film and transferred to fabric using heat and pressure. |

| Equipment Needed | Invest in a quality printer (like modified Epson) and high-quality DTF adhesive powder (like those from Avery) for best results. |

| Choosing Transfer Film | Use films specifically designed for DTF applications (e.g. DuraTrans, WTP) that are durable and compatible with your inks. |

| Ink Quality | Use high-quality, water-based inks (such as those from Sublimation 101 or Inktec) for vibrant, long-lasting prints. |

| Temperature and Pressure | Set heat press between 300°F and 320°F for 15-20 seconds, applying even pressure. |

| Post-Processing Techniques | Allow prints to cure for hours and use protective layers like silicone sheets during transfer. |

| Practice and Experimentation | Test various materials and settings, keeping notes on what works best. |

Summary

Professional-quality DTF transfers can be achieved at home with the proper techniques and tools. This method has become increasingly popular for creating custom apparel and textile art, providing vibrant and durable results. By investing in high-quality equipment, selecting the right films and inks, and mastering your heat application process, you can produce stunning DTF transfers that rival professional prints. The journey to mastering this craft requires practice and experimentation, but the rewards of creating exceptional designs at home are undeniable.