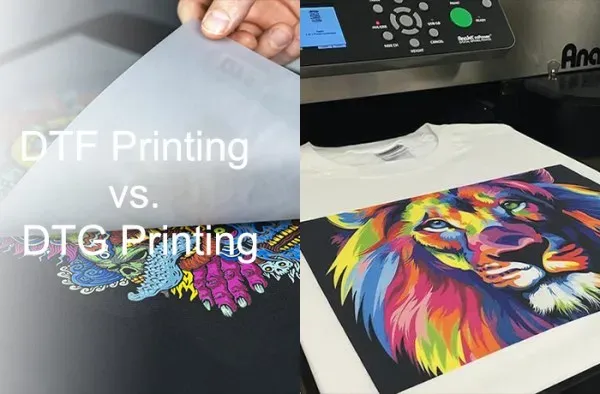

When considering the best printing method for t-shirts, understanding DTF vs DTG printing is essential for achieving the desired results. Both Direct to Film (DTF) and Direct to Garment (DTG) techniques have emerged as leaders in custom apparel printing, each offering unique benefits and capabilities. The differences between DTF and DTG emphasize their respective strengths in image quality, material compatibility, and cost-efficiency. While DTG printing technology excels in detail and vibrant colors on cotton fabrics, DTF printing benefits from adaptability across diverse materials, making it a versatile choice for various applications. This introduction aims to empower you with knowledge about these two innovative printing methods to help you make an informed decision for your printing projects.

In the world of textile creation, choosing between film-based or garment-based printing techniques can be daunting. The contrasting methods of Direct to Film (DTF) and Direct to Garment (DTG) have captured the attention of both artists and businesses alike. As you explore custom fabric printing options, it’s vital to understand how these approaches differ in terms of process, application, and final product quality. DTF, known for its efficiency on multiple fabric types, contrasts sharply with the traditional inkjet approach of DTG, which shines in high-detail designs on natural fibers. This exploration into the printing technologies will guide you through their specific advantages, helping you identify the right fit for your creative needs.

Understanding the Differences Between DTF and DTG Printing

When it comes to choosing between Direct to Film (DTF) and Direct to Garment (DTG) printing, the differences are not just about processes; they encompass varied capabilities and applications tailored to different printing needs. DTF printing involves a transfer film which can adapt to multiple types of fabrics, including cotton, polyester, and blends. This flexibility allows users to manage diverse fabric options effectively, making it an attractive choice for custom apparel printing across a broad range of textiles. On the other hand, DTG printing primarily excels with 100% cotton fabrics, making it ideal for detailed, high-resolution designs that demand pure fabric texture and appeal. Understanding these foundational differences can guide customers in aligning their project needs with the right technology.

Moreover, businesses that focus on custom apparel often consider the scalability of their operations when choosing between DTF and DTG. DTF’s efficiency with smaller orders and versatile applications presents a significant advantage, especially for startups and smaller printing businesses looking to cater to a diverse clientele. Conversely, DTG may be more suited for large production runs where intricate imagery is paramount, allowing for a higher output of high-quality designs. Evaluating these differences not only improves understanding but also aids in deciding the most suitable method for the intended application.

In-Depth Look at DTF Printing Benefits

DTF printing has garnered significant attention for its numerous advantages, making it a compelling choice for custom apparel creators. One of the standout benefits of DTF printing is its material compatibility; it performs exceptionally well on various textiles, including those that may not be ideal for DTG printing. This ability to print on a wide range of materials allows businesses to expand their product lines, appealing to a broader customer base and meeting diverse market demands effortlessly. This adaptability, along with the vibrant color reproduction and design detail achievable with DTF technology, positions it as an innovative choice for any printing operation looking to remain competitive.

Additionally, DTF printing reduces barriers for new entrants into the custom printing market. With lower initial equipment costs compared to DTG, startups can invest in DTF technology without the significant upfront costs usually associated with high-end DTG printers. This financial accessibility, combined with the ease of setup and operation, empowers burgeoning entrepreneurs to explore the possibilities of custom apparel printing creatively. Furthermore, the ability to prepare and store printed transfer films allows for efficient production scheduling, catering well to on-demand printing requests.

Exploring DTG Printing Technology

DTG printing remains one of the most celebrated technologies in the custom apparel domain due to its capacity for producing high-quality images directly on fabric. By utilizing specialized inkjet printers, DTG allows designs to be printed in vibrant colors with striking detail, making it an ideal choice for art-focused prints and personalized designs. The technology handles complex patterns and photographs exceptionally well, which can be critical for businesses aiming to deliver high-value products to discerning customers. With advancements in printing inks and machinery, DTG continues to evolve, providing even greater image durability and softness on the finished garment.

Furthermore, maintenance and calibration of DTG printers can directly influence print quality, making it essential for users to develop a solid understanding of the technology. Depending on modeling, DTG printers may require regular cleaning and adjustments, which can demand expertise from operators. Consequently, while DTG offers unparalleled image quality, assembling the needed skills for operating these machines becomes a pivotal part of running a successful business focused on premium garment printing. This balancing act is part of what makes DTG a respected but intricate choice within the industry.

Comparative Analysis: Cost and Efficiency of DTF vs DTG Printing

Understanding the cost dynamics is crucial for any business looking to invest in custom garment printing. DTG printing, while initially perceived as a higher investment due to the costs of machines and inks, can be quite economical for larger production runs. The cost-per-piece decreases as quantity increases, making DTG printing a more viable option for businesses focused on mass production of high-quality apparel. However, the cost structure for DTF printing is different, often presenting lower upfront costs with more affordable equipment, appealing particularly to smaller businesses that seek quick returns on their investments.

Moreover, with DTF’s technology, businesses find they can scale operations without committing to the high overheads typical of traditional DTG setups. Lower production costs and the ability to efficiently handle diverse fabric types help in minimizing waste and maximizing profit margins. However, it’s essential for businesses to examine their expected order sizes and product types to determine which method not only fits their budget but also optimally aligns with their operational strategies.

Durability and Longevity: DTF vs DTG Printing

In the realm of custom apparel, durability plays a significant role, and both DTF and DTG printing technologies present unique advantages. DTG prints are known for their soft feel and vibrant appearance; however, over time, they may show signs of fading or wear after multiple washes if not treated properly. The type of inks used, along with garment care practices, often dictate the longevity of DTG prints. Properly maintained, these prints can withstand considerable use, making them a wise investment for apparel that emphasizes aesthetics.

Conversely, DTF printing has emerged as a leader in durability due to its robust construction and adhesion properties. DTF prints tend to resist cracking and fading much better than their DTG counterparts, especially after repeated laundering. This makes DTF especially appealing for activewear and items that require frequent cleaning. Therefore, businesses must consider the end-use of their designs when selecting a printing method, with durability and user experience for the final customer being critical metrics in their decision-making process.

Conclusion: Which Printing Method is Right for You?

Navigating the choice between DTF and DTG printing necessitates understanding each method’s strengths and weaknesses in relation to specific project needs. Whether creating high-detailed designs for cotton t-shirts with DTG or leveraging DTF’s versatility for multi-fabric applications, businesses must assess their operational goals and customer expectations. Each technology caters to different requirements, from the vibrancy and intricacy of DTG prints to the adaptability of DTF methods for various materials.

Consequently, the decision also hinges on broader business factors, such as budget, target market, and production volume. With the dynamic nature of the custom apparel market continually shaping printing technology advancements, having a clear grasp of DTF vs DTG will empower businesses to make informed decisions. By aligning printing capabilities with business objectives, companies can harness the full potential of these innovative technologies to meet customer demands and expand their offerings.

Frequently Asked Questions

What are the main differences between DTF and DTG printing?

DTF (Direct to Film) printing uses a transfer film that is printed and then applied to various fabrics, making it versatile for different materials. In contrast, DTG (Direct to Garment) printing applies ink directly onto fabric, primarily suited for 100% cotton. While DTG excels in high-detail designs, DTF allows for broader fabric compatibility.

Which is the best printing method for t-shirts: DTF or DTG?

The best printing method for t-shirts depends on your specific needs. DTF is ideal for a variety of fabrics, including polyester blends, and offers lower startup costs. DTG excels in quality and detail for cotton shirts but can be limited to certain fabric types. Evaluating your design requirements and fabric choices is essential.

What are the benefits of DTF printing compared to DTG printing?

DTF printing offers several benefits, including compatibility with a variety of fabrics, lower initial equipment costs, and ease of production. It produces durable prints that resist cracking and fading. In contrast, DTG printing is limited to cotton fabrics but excels in high-resolution image quality.

How does DTF printing technology differ from DTG printing technology?

DTF printing technology involves printing designs onto a special transfer film, which is then applied to fabrics, allowing for diverse material usage. In contrast, DTG printing technology directly inks designs onto fabric, which is particularly effective for high-detail images on cotton.

Is DTF printing more cost-effective than DTG printing?

DTF printing can be more cost-effective, particularly for small businesses or startups due to its lower equipment costs and flexibility. However, DTG printers can be more efficient for larger production runs on cotton fabrics, reducing ink costs per item. Ultimately, the choice depends on production scale and material needs.

How durable are prints from DTF compared to DTG printing?

DTF prints generally demonstrate excellent durability, resisting cracking and fading even after multiple washes, making them suitable for activewear. While DTG prints are also durable, they may fade over time, especially if not maintained properly. The longevity of prints from both methods can depend on ink quality and fabric care.

| Aspect | DTG Printing | DTF Printing |

|---|---|---|

| Process Overview | Direct inkjet printing onto fabric; ideal for high-detail designs. | Uses transfer film for application on various fabrics, providing versatility. |

| Image Quality | High-resolution output, great for photographs and intricate designs. | Competitive image quality, with recent improvements matching DTG. |

| Material Compatibility | Best for 100% cotton fabrics; limited use with blends. | Compatible with various textiles (polyester, spandex, blends). |

| Cost and Efficiency | Higher initial costs but cost-efficient for large runs. | Lower startup costs, appealing for small businesses; variable ongoing costs. |

| Durability | Good wash resistance but may fade over time. | Excellent durability; resistant to cracking and fading after washes. |

| Ease of Use | Requires careful calibration and maintenance. | More user-friendly, with prep and storage options for printed films. |

Summary

DTF vs DTG printing are two innovative methods that serve different needs in the custom apparel industry. DTG printing, using direct inkjet technology, excels at producing high-quality prints on cotton fabrics, making it ideal for intricate designs. On the other hand, DTF printing uses a flexible transfer film, allowing a broader range of fabric compatibility while remaining effective for smaller order sizes. Both methods have unique pros and cons regarding image quality, costs, and durability, ultimately making the choice between them dependent on specific project requirements.