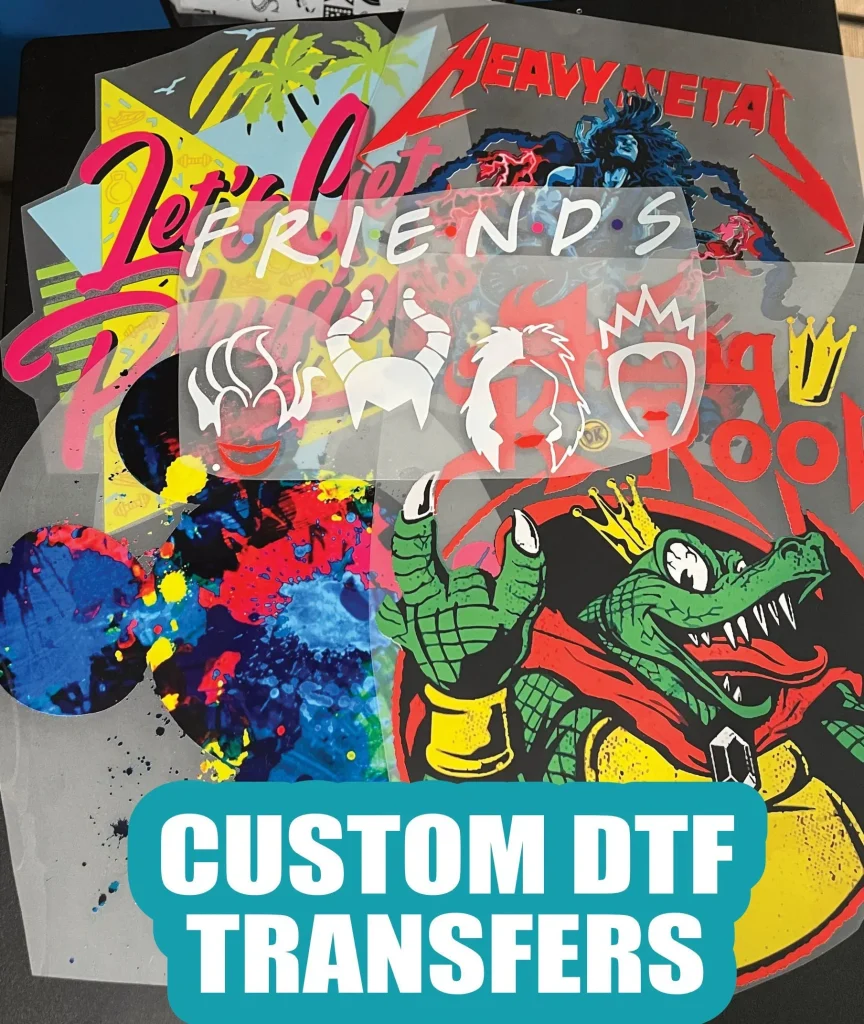

In the realm of custom apparel, particularly t-shirt printing techniques, DTF transfers, or Direct to Film transfers, have emerged as a revolutionary method that enhances quality and efficiency. This innovative approach enables high-resolution designs to be meticulously printed on various fabrics, making it a favored choice among printers. With its user-friendly process and ability to produce vibrant outcomes, DTF printing advantages are compelling for businesses aiming for precision and creativity in their custom apparel printing. The remarkable versatility associated with DTF means it can cater to a range of textile printing innovations, extending beyond just t-shirts to bags and other promotional items. As we explore the intricacies of DTF transfers, you’ll discover how this technology is setting a new standard in the printing industry.

When discussing modern printing methods for apparel, Direct to Film printing stands out as a standout choice among various equipment and techniques. This process, often identified as DTF printing, provides an efficient way to achieve high-quality, detailed outputs on a wide array of fabric types. As one of the latest textile printing innovations, DTF offers user-friendly applications that simplify the customization of designs. Not only does it excel in producing striking colors and intricate patterns, but it also presents numerous advantages over traditional methods like screen printing. In the following sections, we will delve deeper into the functionalities and benefits that make DTF printing an essential asset for businesses venturing into custom apparel.

Understanding Direct to Film (DTF) Printing

Direct to Film (DTF) printing is rapidly gaining popularity as a preferred method for custom apparel printing, especially when it comes to t-shirts. This innovative technique utilizes a unique film to transfer designs onto fabrics, streamlining the process and enhancing design possibilities. Unlike traditional methods like screen printing, DTF printing allows for vivid color reproduction and intricate details, making it an ideal choice for brands that prioritize high-quality visuals in their custom prints.

The DTF printing process is relatively straightforward but highly effective. It begins by printing a digital design onto a special transfer film, which is then coated with a heat-activated adhesive. This method not only eliminates the labor-intensive tasks associated with vinyl printing but also facilitates the application on a variety of fabrics, such as cotton, polyester, and blends. As a result, DTF transfers are becoming a go-to solution for businesses seeking versatile and efficient t-shirt printing techniques.

Advantages of Using DTF Transfers for Apparel

DTF transfers offer multiple advantages that make them a revolutionary choice in the world of custom apparel printing. One of the standout benefits is their versatility; DTF printing can be effectively applied to a wide range of materials beyond just t-shirts, including bags and promotional items. This flexibility allows businesses to diversify their product offerings, catering to a broader customer base while ensuring high-quality prints across different substrates.

Furthermore, DTF printing techniques produce vibrant colors and sharp details that are often unmatched by traditional printing methods. With the ability to withstand repeated washes without fading, these prints maintain their clarity and color, providing a cost-effective solution for businesses concerned about durability. Ultimately, adopting DTF transfers can enhance a brand’s reputation for quality while minimizing costs, particularly for small orders, thus making it an attractive option for custom apparel businesses.

Current Trends Influencing DTF Printing

The landscape of DTF printing is continuously evolving, with several key trends shaping its future. One notable trend is the increasing focus on sustainability within the printing industry. As more companies adopt eco-friendly practices, DTF printing stands out due to its reduced reliance on harsh chemicals and the minimal waste associated with its processes. This shift toward greener technologies not only supports environmental responsibility but also appeals to a growing consumer base that prioritizes sustainability.

Alongside sustainability, there is an observable uptick in the adoption of DTF printing technology across various sectors, from small startups to larger manufacturing companies. The ease of use and efficiency offered by DTF printers have made them an attractive option for businesses looking to enhance their production capabilities. Technological innovations are also playing a crucial role, with advancements in printer quality and materials making DTF printing even more accessible and effective for custom apparel manufacturing.

Exploring T-Shirt Printing Techniques: DTF vs. Others

When assessing various t-shirt printing techniques, it’s essential to understand how DTF printing compares to traditional methods like screen printing and vinyl transfers. DTF transfers provide a unique advantage with their ability to create complex designs with multicolor gradients and fine details, which can be challenging to achieve with screen printing. Additionally, DTF eliminates the need for long setup times and large minimum order quantities, making it an ideal choice for custom jobs and small batches.

In contrast to vinyl printing, where intricate designs often require extensive weeding and layering, DTF printing simplifies the process significantly. The pre-coated adhesive on DTF films ensures a clean and efficient transfer that minimizes production time. Overall, choosing DTF for t-shirt printing not only streamlines workflow but also allows for greater creativity and adaptability, meeting the demands of today’s fashion consumers.

Innovations in Textile Printing: DTF as a Game-Changer

Textile printing innovations have significantly blueprinted the future of custom apparel, with DTF printing emerging as an influential game-changer. The technique introduces a seamless integration of digital technology into the textile printing landscape, allowing businesses to quickly adapt to changing design trends and consumer demands. This adaptability is essential in a fast-paced market where personalization and rapid turnaround times are increasingly sought after.

Additionally, advancements in DTF technology, such as enhanced printer capabilities and improved film quality, continue to drive the industry’s evolution. Innovations not only boost the efficiency and quality of the print output but also expand the range of textiles that can be utilized. As DTF continues to innovate, it promises to redefine what is possible within the realm of textile printing, paving the way for more exciting and diverse fashion expressions.

Getting Started with DTF Printing for Custom Apparel

For apparel businesses looking to leverage the advantages of DTF printing, understanding the initial steps is crucial to success. It begins by selecting high-quality transfer materials and reliable printing equipment that can handle the specific demands of DTF technology. Investing in the right tools will ensure that the intricate designs translate flawlessly onto fabric, yielding high-quality and durable products.

Equally important is mastering effective heat pressing techniques, which are essential for ensuring that transfers adhere properly to different textiles. This crucial step impacts the longevity and vibrancy of the finished design. By researching best practices and staying updated with the latest developments in DTF printing, businesses can position themselves at the forefront of the custom apparel market and provide their customers with stunning, high-quality garments.

Frequently Asked Questions

What are the key benefits of using DTF transfers for t-shirt printing?

DTF transfers, or Direct to Film transfers, offer numerous benefits for t-shirt printing such as versatility in material application, vibrant colors and detailed prints, cost-effectiveness for small orders, and high durability. This innovative method allows for intricate designs to be printed on various fabrics, ensuring quality results that can withstand multiple wash cycles.

How do DTF transfers compare to other t-shirt printing techniques?

DTF printing stands out compared to other techniques like screen printing and vinyl due to its efficiency, vibrant results, and low setup costs. Unlike screen printing, DTF enables detailed designs without weeding, making it faster and simpler. Additionally, DTF can be applied to a wider range of materials, providing flexibility for custom apparel printing.

What materials can be used with DTF printing?

DTF transfers are exceptionally versatile, allowing printing on various fabrics including cotton, polyester, and blends. This adaptability makes DTF an excellent choice for custom apparel printing, not just limited to t-shirts but also extending to bags and promotional items.

Is DTF printing environmentally sustainable?

Yes, DTF printing is increasingly seen as an eco-friendly option compared to traditional printing methods. It typically utilizes water-based inks and generates less waste, making it a sustainable choice for businesses focused on reducing their environmental impact while producing custom apparel.

What advancements are currently happening in DTF printing technology?

Currently, advancements in DTF technology include improved printer capabilities, enhanced transfer films, and innovations in adhesive powders. These developments result in faster, more efficient printing processes and even higher quality outputs, further establishing DTF transfers as a leading choice in textile printing innovations.

Can DTF transfers withstand multiple wash cycles?

Absolutely! One of the significant advantages of DTF transfers is their high durability. The prints maintain their vibrancy and integrity through multiple wash cycles, making them ideal for apparel that is frequently worn, ensuring long-lasting results for custom printed designs.

| Key Point | Description |

|---|---|

| What are DTF Transfers? | DTF Transfers (Direct to Film) is a modern printing technique allowing designs to be transferred onto fabric using heat. |

| How DTF Transfers Work | 1. Printing on film with water-based inks 2. Applying adhesive powder 3. Curing the film 4. Transferring to fabric with heat press |

| Advantages of DTF Transfers | – Versatility for multiple materials – Vibrant colors and detailed designs – Cost-effective for small orders – High durability and washability |

| Current Trends in DTF Transfers | – Sustainability focus – Increased adoption in various sectors – Technological innovations improving efficiency |

Summary

DTF transfers are rapidly reshaping the landscape of custom apparel printing, particularly within the t-shirt printing sector. This innovative printing method marries digital technology and versatile application, allowing for elaborate designs to be easily and effectively transferred onto a variety of fabrics. As the fashion and printing industries shift towards sustainability and quality, DTF transfers are emerging as a preferred choice for businesses and consumers alike. With their ability to produce vibrant prints that endure the rigors of wear and wash, DTF transfers not only enhance aesthetic appeal but also meet the practical demands of modern clothing. By leveraging the advantages of DTF technology, companies can stay ahead in a competitive market, embracing the future of custom prints.