In the rapidly evolving world of custom T-shirt printing, **DTF transfers** are revolutionizing the industry with their innovative approach. Direct-to-Film technology enables designers to create vibrant, high-quality prints that adhere seamlessly to various fabrics, making it a game changer for businesses looking to stand out. This cutting-edge method not only enhances creativity but also streamlines the printing process, allowing for print-on-demand solutions that cater to unique customer preferences. As more entrepreneurs embrace DTF technology, the shipping and turnaround times for custom apparel are reduced, thus boosting overall efficiency and customer satisfaction. Discover how DTF transfers can elevate your custom printing endeavors and differentiate your brand in a competitive marketplace.

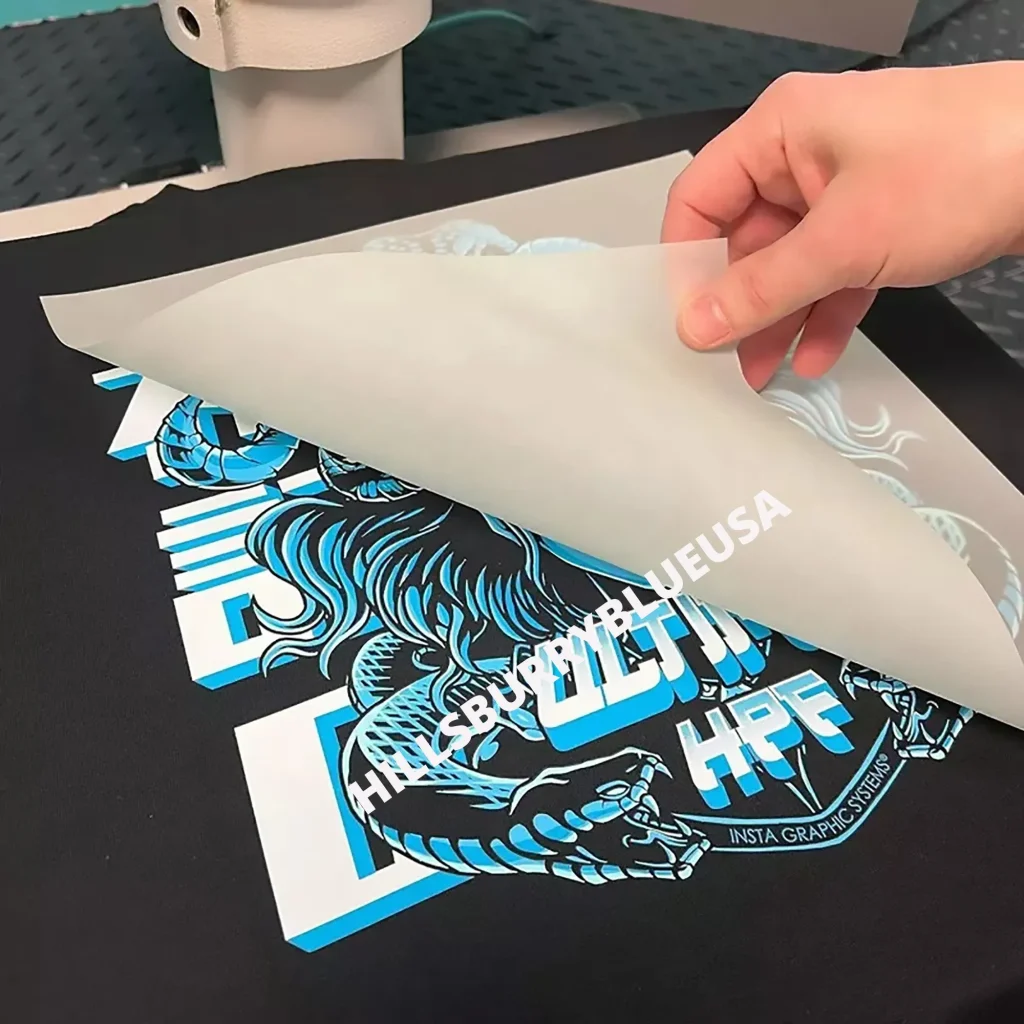

Known as Direct-to-Film printing, DTF transfers represent a significant leap in the customization of apparel, particularly for personalized merchandise like T-shirts. This advanced printing technique involves applying designs onto a specialized film that can then be transferred onto fabric using heat and pressure. Businesses can now achieve excellent durability and detail in their designs, making this method not only efficient but also reliable. As a versatile choice across different fabric types, from cotton to blends, DTF technology is paving the way for bespoke creations in the custom apparel sector. The rise of this innovative printing process marks a pivotal shift in how brands manage their custom print runs and engage with various fashion niches.

Understanding the Benefits of DTF Transfers

The rise of Direct-to-Film (DTF) transfers presents an opportunity for those in custom T-shirt printing to elevate their offerings significantly. This method provides a unique blend of vivid color reproduction and exceptional durability, making it a preferred choice for printing intricate designs. Unlike other traditional methods, DTF technology allows for detailed artwork to be displayed clearly on diverse fabrics, enhancing the overall appearance of custom apparel. With the growing demand for unique and personalized clothing, DTF transfers stand out as an effective solution to meet these needs.

Furthermore, DTF transfers are known for their versatility, being applicable to various fabric types such as cotton, polyester, and blends. This adaptability makes DTF an ideal choice for businesses looking to broaden their product range, thus attracting different customer segments. As the competition in the garment industry heats up, adopting DTF technology can empower brands to stand apart by offering high-quality, eye-catching prints that resonate with consumers.

How DTF Transfers Compare to Other Printing Methods

When evaluating different techniques for custom T-shirt printing, DTF transfers emerge as a superior alternative to methods like Direct-to-Garment (DTG) or traditional screen printing. DTF technology allows for prints that not only look better but also last longer, making it a wise investment for businesses. Unlike DTG, which can struggle with fabric compatibility and often requires specialized textiles, DTF can seamlessly adhere to a wider variety of materials, from soft cotton to synthetic blends.

Moreover, the simplicity of the DTF process requires less setup time compared to screen printing, where intricate setups can lead to longer production times and increased costs. This efficiency is particularly beneficial for small businesses and print-on-demand operations, allowing them to respond quickly to customer demands without compromising on quality. In essence, DTF transfers facilitate a more agile and responsive business model, making them a clear choice in today’s fast-paced market.

The Role of Technology in DTF Transfers

The rapid evolution of printing technology has played a crucial role in the success of DTF transfers. With advancements in printer capabilities, such as higher resolutions and larger print areas, businesses can exploit DTF technology to produce vibrant prints efficiently. Recent innovations, such as the LOKLiK iPrinter and compact A3 DTF printers, simplify the printing process and empower more users to explore their creative potential without the need for extensive training or experience.

Additionally, DTF technology’s compatibility with various design software enables creators to generate compelling visuals easily. This accessibility not only encourages designers to experiment with their artwork, but it also significantly widens the availability of DTF products on the market. As a result, businesses can tap into new audiences more effectively, fueling the growth of custom apparel and expanding the realm of possibilities in this space.

Optimizing Your Business with DTF Transfers

To harness the full potential of DTF transfers, businesses should prioritize investing in quality DTF printers and equipment. Opting for high-resolution printers with the capability to handle large designs can enhance the final product’s detail and vibrancy. Moreover, understanding the nuances of DTF materials, such as the types of films and inks used in the printing process, can significantly impact the quality of prints and overall customer satisfaction.

Another strategic approach is to create unique, eye-catching designs that leverage the strengths of DTF technology. Bold graphics, intricate patterns, and mixed media concepts can attract customers looking for standout apparel. Marketing those custom creations effectively, utilizing social media platforms, and highlighting the advantages of DTF transfers—like durability and exceptional quality—can further enhance your brand’s visibility and appeal.

Recent Innovations in DTF Technology

Recent advancements in DTF technology, including the launch of custom transfer printing services by platforms like DesignBundles.net, reflect the industry’s commitment to improving user experience. These innovations make DTF technology accessible for both seasoned professionals and newcomers alike, dramatically streamlining the process of creating high-quality prints. With such developments, creators can focus more on their designs and less on the technical hurdles associated with traditional printing methods.

Additionally, growing companies, such as Eazydtf, are expanding their capacity to meet the skyrocketing demand for DTF printing services. The introduction of more robust printing equipment is crucial to providing timely services and satisfying the ever-increasing needs of custom apparel consumers. As new entrants continue to emerge in the DTF arena, businesses that stay informed about technology trends will maintain a competitive edge in the market.

The Future of Custom T-Shirt Printing with DTF Transfers

Looking ahead, the future of custom T-shirt printing appears bright with the ongoing integration of DTF transfers into the mainstream. As this technology continues to advance, businesses of all sizes can benefit from the seamless production of high-quality, custom designs without sacrificing speed. The increasing adoption of DTF printing within print-on-demand models indicates a shift towards more personalized and creative offerings in the apparel market.

Furthermore, the synergy between innovative printing solutions and the rise of e-commerce highlights a transformative shift in how consumers shop for clothing. As customers seek out unique pieces, the ability to deliver intricate designs quickly and affordably through DTF technology provides businesses with substantial growth opportunities. This promising trajectory underscores the critical role of DTF transfers in shaping the future of the custom apparel industry.

Frequently Asked Questions

What are DTF transfers and how do they work?

DTF transfers, or Direct-to-Film transfers, involve printing a design onto a special film and then transferring it onto fabric using heat and pressure. This method offers vivid colors and strong adherence, making it a popular choice in custom T-shirt printing.

Why are DTF transfers becoming popular in custom T-shirt printing?

DTF transfers are gaining popularity due to their versatility with different fabrics, cost-effectiveness, high-quality output, and ease of use. This technology allows businesses to create vibrant custom prints quickly, appealing to a broad customer base.

How does DTF technology compare to Direct-to-Garment (DTG) printing?

DTF technology differs from DTG printing in that it uses a film transfer process, allowing for better color vibrancy and fabric compatibility. While DTG is best suited for 100% cotton, DTF transfers can be applied to a variety of materials, making it more versatile for custom apparel.

What kind of equipment is needed for high-quality DTF transfers?

To achieve high-quality DTF transfers, it’s essential to invest in a reliable DTF printer that offers excellent print resolution and size capabilities. Additionally, an efficient heat press is necessary to ensure proper transfer of designs onto garments.

Can DTF transfers be used for print-on-demand businesses?

Yes, DTF transfers are highly suitable for print-on-demand businesses. With their cost-effectiveness, simplicity, and ability to produce high-quality prints on various materials, DTF technology allows entrepreneurs to fulfill custom orders efficiently.

What steps should I take to market my DTF transfer products effectively?

To market DTF transfer products, showcase unique designs on social media and e-commerce platforms. Highlight the benefits of DTF printing—such as durability and vibrant colors—in promotional materials and consider targeting niche markets to expand your reach.

| Key Points | Details |

|---|---|

| What are DTF Transfers? | A method of printing designs onto film and transferring them to fabric using heat and pressure. |

| Why DTF Transfers are Gaining Traction | 1. Versatility with various fabrics. 2. Cost-effective compared to screen printing. 3. High quality and durability of prints. 4. Simple operation for users. |

| Recent Developments in DTF Technology | 1. Custom transfer printing launched by DesignBundles.net. 2. The LOKLiK iPrinter handles oversized designs. 3. Compact A3 DTF printer for South Africa’s market by AM.CO.ZA. 4. Eazydtf expands with large-format printers. 5. Snuggle DTF platform for easier commercial printing. |

| How to Leverage DTF Transfers | 1. Invest in quality equipment. 2. Create unique designs. 3. Market effectively on social media. 4. Expand into new product niches. |

Summary

DTF transfers are revolutionizing the world of custom T-shirt printing. As a cutting-edge technology, these transfers offer unmatched versatility, cost-saving advantages, and a high-quality finish that appeals to a growing market. By adopting DTF printing techniques, businesses can cater to diverse customer needs, enhance their creative capabilities, and streamline their operations, which directly impacts their success in the competitive apparel landscape. Embracing DTF transfers not only elevates product offerings but also supports efficient workflows, making it a vital tool for any business looking to thrive in the custom printing industry.