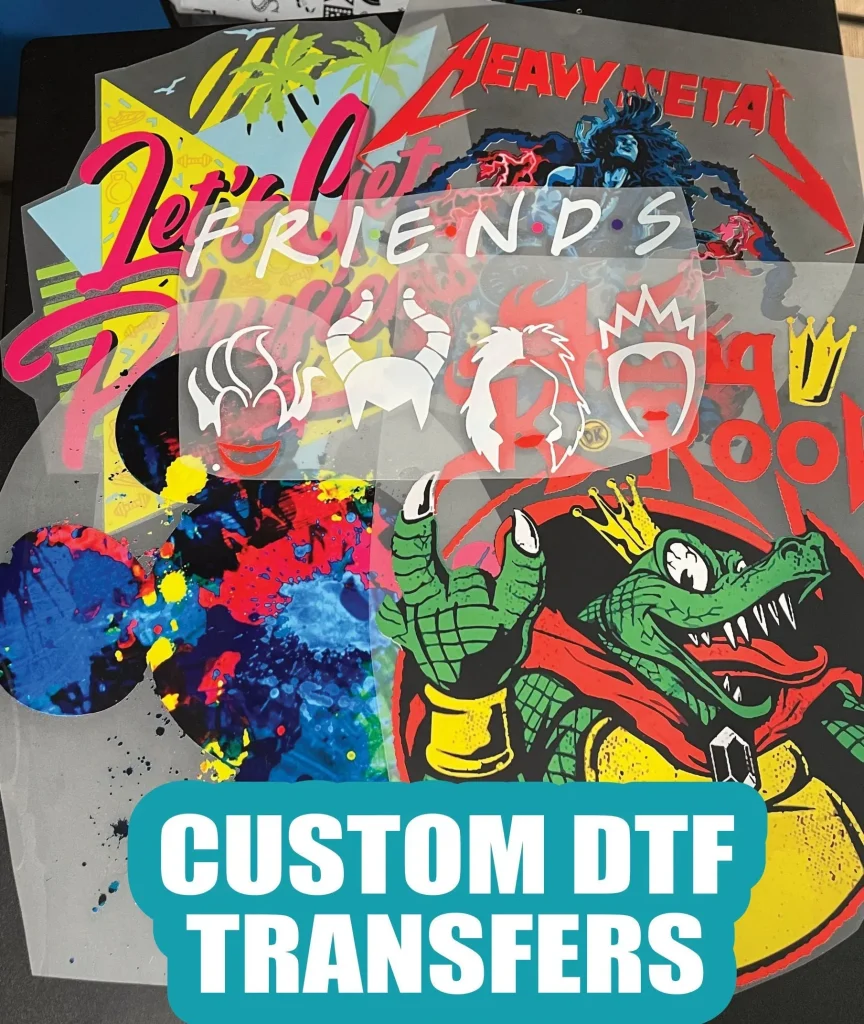

DTF transfers, or Direct to Film transfers, are revolutionizing the textile industry by providing an innovative way to create vibrant and durable prints on various fabrics. This cutting-edge printing method streamlines the process of transferring intricate designs onto garments, ensuring that colors are bright and last through multiple washes. As more designers and businesses embrace DTF printing technology, understanding some essential DTF transfer tips becomes crucial for achieving the best results. In this article, we’ll delve into the fascinating DTF printing process, sharing key insights to help you master your prints. Whether you’re new to printing or looking to enhance your skills, these techniques will ensure your creations pop with intensity and consistency.

Often referred to as Direct to Film printing, DTF transfers have emerged as a game-changer in the textile printing market. This method expertly combines the flexibility of digital printing with the robustness of traditional transfer techniques. Many enthusiasts now seek out practical DTF transfer tips to maximize the output quality and durability of their designs. By leveraging the unique DTF printing process, creators can achieve an array of vibrant prints that appeal to both fashion and merchandising sectors. As we explore the nuances of this innovative printing approach, you’ll discover how to elevate your textile projects using these dynamic solutions.

Understanding the DTF Printing Process

The DTF printing process involves a series of well-defined steps that begin with printing a design onto a special film. This film serves as the medium onto which high-quality inks are applied using advanced Direct to Film printing techniques. Once the design is printed, powder adhesive is sprinkled onto the wet ink, ensuring that the ink sticks firmly and facilitates a seamless transfer. This innovative approach allows for precise detail and a broader color range than traditional methods, making it an attractive option for designers seeking to create stunning textiles.

After the powder adhesive is applied, the film is cured using a heat source. This step activates the adhesive and solidifies the connection between the ink and the film, making the transfer process successful. When the transfer is later applied to the garment using a heat press, the ink adheres effectively, resulting in vibrant prints that remain intact even after multiple washes. Understanding each stage of the DTF printing process is crucial for designers and print professionals aiming to achieve high-quality results.

Tips for Achieving Vibrant Prints with DTF Transfers

To create vibrant prints using DTF transfers, it’s essential to focus on the quality of the materials you’re using. Selecting high-grade DTF inks is one of the most critical steps to ensure your colors are bright and eye-catching. Many professionals recommend pigment-based inks for their ability to produce richer colors compared to dye-based alternatives. Additionally, using high-quality DTF film that is optimized for this printing method can make a significant difference in the vibrancy and clarity of the final output.

Beyond the materials, fostering a conducive printing environment by optimizing your printer settings can enhance the vibrancy of your prints. Adjusting the resolution, color balance, and ink density parameters will allow you to exploit the full potential of your inks and films. Combining these strategies can transform the standard DTF transfer into a visually striking piece that stands out in any textile application.

Essential DTF Transfer Tips for Durability

Durability is a key aspect of successful DTF transfers, and several strategies can be implemented to enhance the longevity of your prints. Firstly, using a robust adhesive that is specifically designed for DTF applications ensures excellent bonding between the ink, film, and garment. Furthermore, the curing process must be treated with precision. Adhering to the recommended temperature and pressure settings will create a strongcoating that withstands regular wear and washing.

Additionally, allowing the prints to cure adequately before handling or washing them is vital. This resting period promotes optimal adhesion and reduces the risk of peeling or fading. Coupled with proper care instructions post-application—such as washing inside out and avoiding harsh detergents—can significantly contribute to sustaining the vibrancy and durability of your DTF transfers for many washes.

Garment Preparation for Successful DTF Transfers

Prior preparation of the garment plays a crucial role in the success of the DTF transfer application. Ensuring that the fabric is clean, pre-washed, and free of any chemicals or residues is imperative for optimal adhesion. Fabrics that have been treated with fabric softeners or protective coatings can hinder the transfer’s ability to bond effectively, leading to disappointing results. By initiating the process with a thorough cleaning, you create an ideal canvas for your vibrant designs.

Moreover, selecting the right type of fabric is another component of preparation. DTF transfers can be applied to a variety of materials including cotton, polyester, and blends. However, understanding how different fabrics react to heat and pressure during transfer application can influence the outcome. Fabrics with smooth and stable surfaces typically yield the best results, allowing for a clean imprint that showcases your artwork to its fullest potential.

Proper Storage Techniques for DTF Transfers

After printing your DTF transfers, maintaining their quality through proper storage techniques is crucial. Transfers should be kept in a cool, dry environment to prevent deterioration caused by humidity and heat. The ideal storage conditions will protect the film and adhesive from environmental factors that could compromise the adhesion and vibrancy of the prints. By being mindful of the storage conditions, you can safeguard the effectiveness of your transfers until they are ready for application.

Additionally, utilizing protective storage materials, such as moisture-resistant bags or containers, can further extend the life of your DTF transfers. Avoid stacking heavy items on top of transfers to prevent unintended creases or indentations, which can interfere with successful application. By implementing these best practices, your DTF transfers will remain in top condition, ensuring they deliver optimal results when the time comes to apply them.

Post-Application Care for DTF-Printed Garments

To maximize the lifespan of your DTF-printed garments, post-application care is just as critical as the initial transfer process. Wait at least 24 hours before washing the garment to allow the ink to cure fully, ensuring a secure bond with the fabric. When it is time to clean, opt for a gentle washing cycle and always turn the garment inside out. This extra precaution protects the print from friction and potential damage during the wash.

It is also advisable to avoid using bleach or fabric softeners, as these can degrade the adhesion of the print over time. Instead, consider using mild detergents that are safe for printed textiles. Following these care instructions will help maintain both the vibrancy and durability of DTF transfers, allowing your designs to look fresh and striking for many wears to come.

Frequently Asked Questions

What are DTF transfers and how do they work?

DTF transfers, or Direct to Film transfers, involve printing a design onto a special film that is then heat-pressed onto a garment. This method allows for vibrant prints and is suitable for a variety of fabrics, including cotton and polyester. The DTF printing process includes three key stages: printing, powder application, and heat transfer, ensuring that designs are durable and retain their vibrancy.

What are some essential DTF transfer tips for vibrant prints?

To achieve vibrant prints with DTF transfers, focus on using high-quality DTF film and vibrant inks, optimize printer settings for resolution and ink density, and perfect the curing process according to manufacturer guidelines. These DTF transfer tips can significantly enhance the color and detail of your final prints.

How does the curing process affect DTF printing?

The curing process is critical in DTF printing as it ensures proper adhesion between the ink and the garment. If the curing temperature and pressure are not correctly set, it can lead to issues like peeling or fading of vibrant prints. Following the recommended settings and pre-heating the garment can optimize results.

What should I consider when preparing garments for DTF transfers?

When preparing garments for DTF transfers, ensure they are clean and dry without any residues that might affect adhesion. Pre-washing the fabric can remove any chemical treatments that may cause adhesion issues, leading to more durable and vibrant prints post-application.

How can I store DTF transfers to maintain print quality?

To maintain print quality, DTF transfers should be stored in a cool, dry environment that protects them from moisture and heat. Proper storage is essential to prevent adhesion failure and preserve the vibrancy of the prints until they are applied.

What are some post-press care tips for DTF printed garments?

To enhance the longevity of DTF printed garments, let the prints cure for at least 24 hours before washing. Wash the garments inside out using mild detergents, and avoid fabric softeners to protect the prints. Following these care tips helps maintain the vibrancy and durability of your DTF transfers.

| Key Points | Details |

|---|---|

| What are DTF Transfers? | A printing method transferring designs onto garments using a special film, suitable for various fabrics. |

| Quality Materials Matter | Invest in high-quality DTF films, vibrant inks, and strong powder adhesives for best results. |

| Optimize Print Settings | Adjust resolution, color settings, and prefer pigment-based inks for vibrant outputs. |

| Perfecting the Curing Process | Follow recommended heat press settings to ensure proper ink adhesion. |

| Prepare the Garment Carefully | Ensure garments are clean and free from residues to avoid print issues. |

| Storage of Transfers | Store in cool, dry conditions to protect against humidity and heat damage. |

| Post-Press Care for Longevity | Allow prints to cure for 24 hours and wash inside out with safe detergents. |

Summary

DTF Transfers have revolutionized the textile printing landscape, providing a vibrant and durable alternative to traditional methods. By following essential techniques, such as using high-quality materials, optimizing print settings, and ensuring proper garment care, one can achieve impressive and long-lasting results. The practice goes beyond mere printing; it embodies an art form that blends creativity with technical precision. Staying updated on the latest advancements and trends in DTF printing will further enhance your abilities and output, ensuring your designs not only stand out but also withstand the test of time.