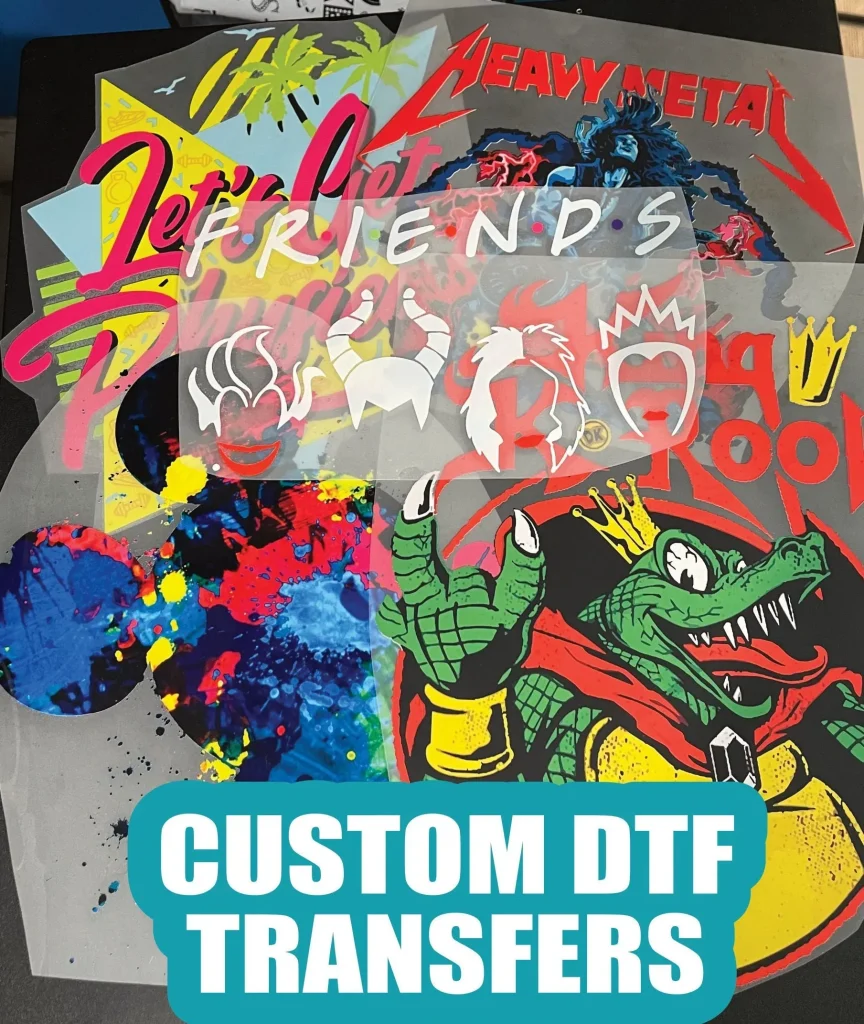

In the ever-evolving landscape of custom apparel printing, **DTF transfers** have rapidly gained traction as a transformative technology that redefines how designs are applied to fabrics. Standing for Direct-to-Film printing, this method offers remarkable advantages, including vibrant colors and exceptional detail that make every piece of clothing a canvas for creativity. By printing designs onto a special film which is then transferred onto various fabrics, businesses can achieve high-quality results that cater to both individual consumers and larger retail needs. The benefits of DTF transfers extend beyond visual appeal; they also include cost efficiency, speed, and compatibility with diverse materials, making them an ideal choice for custom clothing production. Whether you’re a startup or an established brand, embracing DTF transfers can set you apart in the competitive market of sustainable apparel printing and enhance your offerings significantly.

When it comes to innovative methods in custom garment decoration, Direct-to-Film (DTF) printing shines as a standout choice for creators and manufacturers alike. This technology employs a specialized transfer film that allows for intricate and colorful designs to seamlessly adhere to a wide range of textiles, enhancing the overall aesthetic of the final product. As businesses in the realm of custom clothing production seek cost-effective and efficient solutions, DTF transfers offer an impressive array of benefits, from speedy production times to versatility in material compatibility. In an age where sustainability is paramount, DTF’s minimal waste generation positions it as an eco-friendly option that aligns well with modern consumer values. By harnessing the power of DTF transfers, brands can elevate their custom apparel offerings while promoting a responsible approach to printing.

Understanding DTF Transfers and Their Mechanism

DTF transfers, or Direct-to-Film transfers, are a revolutionary printing technology that has significantly changed the landscape of custom apparel production. This method allows designers to create high-quality images that are printed onto a specific film, which is then transferred onto the fabric with the use of heat. The appeal of DTF transfers lies in their ability to produce intricate designs with vibrant colors and high resolution, making them suitable for a variety of custom clothing applications. Not only do DTF transfers provide an excellent finish, but they also have a quick setup time, making them an efficient option for businesses looking to streamline their production processes.

Moreover, understanding the underlying technology of DTF transfers can help businesses harness their full potential. The flexibility of this method allows for the reproduction of detailed patterns that can cater to unique branding needs. It combines the advantages of traditional screen printing with the modern capabilities of digital printing, offering an alternative that can appeal to a broader range of designers and custom apparel producers. With DTF transfers, the possibilities are endless in terms of design complexity and overall garment appeal.

Advantages of DTF Transfers in Custom Apparel Production

DTF transfers come with a variety of significant advantages that make them a preferred choice in the custom apparel industry. One of the primary benefits is the ability to produce high-quality prints that maintain clarity and vibrancy even after multiple washes. This durability ensures that designs not only look good upon delivery but also last throughout the lifespan of the garment. Furthermore, the ability to print complex images without compromising on quality allows for a wider range of creative expression for apparel brands, which can be crucial in standing out in a crowded market.

Additionally, DTF transfers offer cost-effective solutions for both small businesses and larger enterprises. The need for precision and quality at a lower price point positions DTF as an attractive option for startups and businesses that focus on custom clothing production. By minimizing waste through efficient transfer processes and allowing for small batch production, DTF helps brands manage their operational expenses effectively while maintaining high standards of quality.

Speed and Efficiency of DTF Printing

The custom apparel industry thrives on efficiency, and DTF transfers are designed to enhance production speed. Unlike traditional methods that require lengthy setup processes, DTF printing allows for on-demand production, enabling businesses to react quickly to market demands. This efficiency is particularly beneficial for companies handling rush orders or those that want to expand their product offerings rapidly. Customers today expect quick turnarounds, and DTF transfers fulfill that need efficiently.

Moreover, the streamlined workflow associated with DTF transfers means that businesses can increase their order fulfillment capacity. With the ability to print multiple designs at once on gang sheets, organizations can optimize their printing operations further, thereby reducing lead times. The impact of this efficiency is significant, as it fosters customer satisfaction and drives repeat business, which are vital components in the growth of a successful custom apparel brand.

Exploring Material Compatibility with DTF Transfers

One of the standout features of DTF transfers is their extensive compatibility with a wide variety of materials. From cotton and polyester to blends of these fabrics, DTF printing opens up numerous opportunities for apparel design. This adaptability is essential for businesses aiming to cater to diverse markets and consumer preferences. Whether producing sportswear, casual fashion, or corporate apparel, the ability to work with multiple fabrics enhances the versatility of the product offerings.

Furthermore, the compatibility of DTF transfers with different materials allows brands to experiment with innovative designs while ensuring high-quality results. This flexibility is a significant advantage for designers who wish to incorporate various textures and styles into their collections. As the custom clothing market becomes increasingly competitive, leveraging material compatibility through DTF printing can position brands as leaders in quality and creativity.

The Sustainability of DTF Transfers in Apparel Printing

In an age where consumers are increasingly aware of environmental issues, the sustainability of production methods is crucial. DTF transfers generate considerably less waste compared to traditional printing techniques, making them an environmentally friendly choice for custom apparel businesses. The ability to print designs directly onto film allows for precise transfers that minimize leftover materials, aligning well with sustainable apparel printing practices. This reduction in waste not only benefits the planet but also decreases overall printing costs for manufacturers.

Moreover, embracing sustainable practices through DTF transfers can appeal to eco-conscious consumers, providing an opportunity for brands to enhance their market positioning. By showcasing their commitment to reducing environmental impact, businesses can attract a loyal customer base dedicated to supporting brands that prioritize sustainability alongside quality. This merging of ethics with high-standard printing technology creates a compelling narrative for brands looking to thrive in today’s eco-aware marketplace.

Unlocking Customization Potential with DTF Transfers

Customization remains a key demand in the fashion industry, and DTF transfers provide unmatched potential for personalized apparel. With the ability to create intricate designs tailored specifically for individual customers, DTF printing opens up a world of opportunities for brands to engage deeply with their audience. This level of personalization not only boosts customer satisfaction but also enhances brand loyalty as customers enjoy unique pieces that reflect their individuality.

Moreover, as the demand for customized products continues to rise, leveraging DTF transfers can position businesses well within the niche of custom clothing production. The high-definition quality of DTF prints allows brands to deliver exceptional personalized garments that appeal to a wide range of customers—from sports teams needing uniform designs to individuals seeking unique fashion statements. By integrating DTF transfer technology, brands can meet the growing demand for customization effectively and holistically.

Frequently Asked Questions

What are DTF transfers and how do they work in custom apparel printing?

DTF transfers, or Direct-to-Film transfers, are a printing technique where designs are printed on a special film and then heat-transferred onto fabric. This method allows for vibrant, high-quality graphics and supports intricate designs, making it a popular choice in the custom apparel printing industry.

What are the benefits of DTF transfers for custom clothing production?

The benefits of DTF transfers for custom clothing production include high-quality prints, quick production times, cost-effectiveness, compatibility with various materials, and sustainable printing practices. These features make DTF an ideal choice for businesses aiming to create visually appealing and eco-friendly apparel.

How does DTF printing enhance the customization options for apparel businesses?

DTF printing enhances customization for apparel businesses by allowing intricate designs to be printed with precision. The technology supports small runs and personalized orders, enabling brands to cater to unique customer preferences while maintaining high-quality output.

Is DTF transfer printing more cost-effective than traditional printing methods?

Yes, DTF transfer printing is typically more cost-effective than traditional methods like screen printing, especially for small batches. It requires a lower initial investment and allows for efficient production of custom apparel, making it an attractive option for startups and small businesses.

What materials are compatible with DTF transfers for sustainable apparel printing?

DTF transfers are compatible with a wide range of materials, including cotton, polyester, leather, and blends. This versatility allows apparel designers to create sustainable clothing across various fabric types while minimizing waste during production.

How does DTF printing support eco-friendly practices in the custom apparel industry?

DTF printing supports eco-friendly practices by minimizing waste generation through efficient printing directly onto film. Its ability to produce customized designs reduces excess materials and off-cuts, aligning well with the sustainability goals of modern custom apparel production.

| Key Benefits of DTF Transfers | Description | Advantages | |

|---|---|---|---|

| High-Quality Transfers | Produces detailed, vibrant designs and supports intricate artwork. | ||

| Speed and Efficiency | Quicker production cycles and on-demand printing ability. | ||

| Cost-Effectiveness | Lower initial investment and small batch production capabilities. | ||

| Wide Material Compatibility | Compatible with cotton, polyester, leather, and blends. | ||

| Customization and Sustainability | Less waste and high customization potential for eco-friendly practices. | ||

Summary

DTF transfers are revolutionizing the world of custom apparel, offering a range of compelling benefits that address the needs of modern designers and businesses. With high-quality outputs that showcase vibrant colors and detailed artwork, DTF transfers enable brands to differentiate themselves in a competitive market. Additionally, the efficiency of DTF technology facilitates rapid production cycles, reducing turnaround times and enhancing customer satisfaction. Cost-effectiveness is another notable advantage, particularly for small businesses, as DTF allows for lower initial investments and the ability to produce small, customized runs. Moreover, DTF transfers boast wide compatibility with various materials, making them versatile for different apparel types. Importantly, DTF printing aligns with sustainable practices by minimizing waste and promoting eco-friendly options. In summary, embracing DTF transfers not only enhances product offerings but also positions brands favorably in the ever-evolving landscape of custom apparel.