DTF transfers are rapidly transforming the landscape of custom apparel printing, emerging as a preferred choice for businesses and creatives alike. This innovative technology, also known as Direct to Film printing, offers vibrant and durable designs that can be applied to a wide variety of fabrics. DTF heat transfers provide significant advantages over traditional methods, making them a game-changer in the realm of custom printing solutions. With a focus on quality and versatility, DTF printing benefits have made it easier than ever for companies to meet the growing demand for personalized apparel. As we dive deeper into this exciting development, you’ll discover how DTF transfers are setting new standards in the industry and reshaping the future of fashion.

Also referred to as Direct to Film transfer technology, DTF printing is revolutionizing the custom clothing industry with its unique approach to fabric decoration. This method involves applying designs onto a specialized film that ensures high-quality, vivid prints that stand the test of time. Unlike other printing techniques, such as screen printing or sublimation, DTF offers unparalleled versatility, allowing prints on various materials from cotton to leather. As businesses and creatives seek innovative custom printing solutions, understanding the dynamics of DTF transfers becomes crucial for tapping into the colorful world of custom apparel.

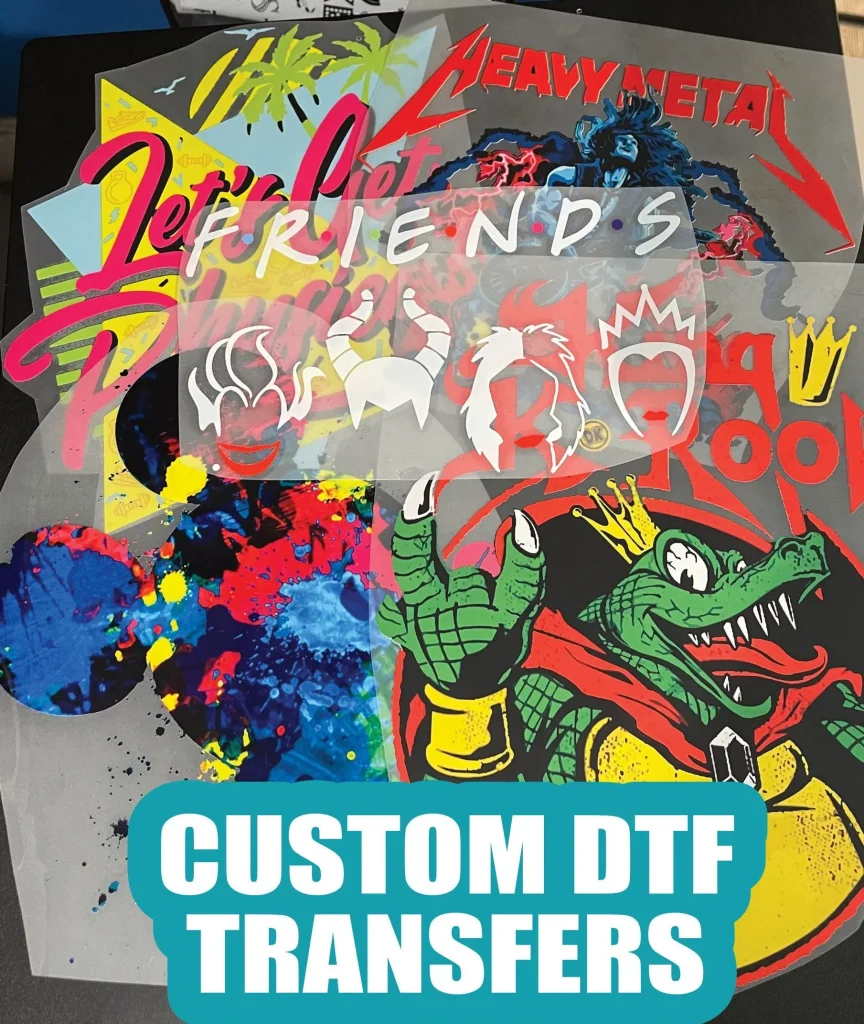

Understanding the Basics of DTF Transfers

DTF transfers, or Direct to Film transfers, provide a cutting-edge solution for custom apparel printing that meets the demands of modern designers and businesses alike. By applying your designs to a thin film and using heat to transfer them onto fabric, this method opens up possibilities that traditional printing techniques simply can’t match. With DTF transfers, the adaptability to various textiles—ranging from cotton to polyester and beyond—makes it a versatile choice for any custom project.

Furthermore, the technology behind DTF printing is quite sophisticated, utilizing specialized inks that blend durability with aesthetic appeal. This results in vibrant colors that can withstand repeated washing and wear, ensuring that your creative designs remain intact long after they’ve been printed. Businesses looking to offer custom solutions can find great value in DTF transfers, as they cater to both small and large orders without sacrificing quality.

Frequently Asked Questions

What are DTF transfers and how do they work in custom apparel printing?

DTF transfers, or Direct to Film transfers, involve printing designs onto a special film that can be transferred onto various fabrics using heat and pressure. This method is versatile, allowing high-quality prints on materials like cotton, polyester, and leather, making it a cutting-edge solution for custom apparel printing.

What are the key benefits of using DTF printing in custom apparel?

DTF printing offers several benefits, including versatility in fabric types, cost-effectiveness for small orders, ease of use without complex techniques, and high-quality outputs that are durable and vibrant. These advantages make DTF transfers an excellent choice for businesses in the custom apparel market.

How do DTF heat transfers compare to traditional printing methods?

DTF heat transfers surpass traditional methods, such as screen printing and sublimation, in several ways: they can be applied to a wider range of fabrics, eliminate minimum order requirements, and provide exceptional print quality. This flexibility and high-quality output make DTF printing a preferred choice in the custom apparel industry.

What recent advancements have been made in DTF printing technology?

Recent advancements in DTF printing technology include new products like Sam’s DTF Transfers’ premium services and Insta Graphic Systems’ advanced DTF heat transfers. These innovations enhance color vibrancy and print durability, catering to the growing demand for custom apparel solutions across various markets.

Can small businesses benefit from using DTF transfers for custom printing solutions?

Yes, small businesses can greatly benefit from DTF transfers as they allow for small volume orders with no minimum requirements. This cost-effective and easy-to-use technology empowers entrepreneurs to offer unique custom apparel without the financial burden of traditional printing methods.

What is the future outlook for DTF transfers in the custom apparel industry?

The future of DTF transfers in the custom apparel industry looks promising, with advancing technologies and increasing accessibility for all businesses. As brands continue to invest in DTF printing solutions, customer demand for personalized and high-quality apparel will shape trends and innovations in the market.

| Key Point | Details |

|---|---|

| Overview of DTF Transfers | DTF transfers involve printing designs on a special film for transfer onto various fabrics, using heat and pressure. |

| Recent Developments | 1. Sam’s DTF Transfers launched premium no-minimum services. 2. Insta Graphic Systems introduced advanced heat transfers. 3. DTFPrinter created a custom transfer experience for crafters. 4. AM.CO.ZA released a compact A3 DTF printer for small businesses. |

| Advantages of DTF Printing | – Versatile fabric compatibility – Cost-effective for low volume orders – Easy application process – Durable and vibrant prints |

| Future of DTF in Custom Apparel | DTF transfers are expected to lead the custom apparel market, enhancing product offerings and supporting a sustainable print industry. |

Summary

DTF transfers are revolutionizing the custom apparel printing landscape, establishing themselves as a key player in the industry. This innovative method allows for vibrant and durable designs on a variety of fabric types, making it an attractive option for businesses aiming to cater to a diverse market. Recent advancements by industry leaders like Sam’s DTF Transfers and Insta Graphic Systems demonstrate the rapid evolution and growing accessibility of this technology, enabling brands to fulfill personalized demands while maintaining high quality. As the DTF transfer technology continues to develop, it will undoubtedly shape the future of custom apparel, providing unlimited creative possibilities for both emerging and established businesses in the marketplace.