DTF transfers, or Direct-to-Film transfers, are at the forefront of a seismic shift in the custom apparel printing industry. This cutting-edge printing technology combines high-quality output with a versatile application range, offering businesses the ability to create stunning designs on various fabrics effortlessly. With DTF printing, the possibilities for personalized apparel are virtually limitless, enabling artists and brands to turn their visions into reality. As more companies adopt this innovative approach to apparel printing, the demand for DTF transfers continues to surge, driven by consumers’ desire for uniqueness and quality. Join us as we explore how DTF transfers are revolutionizing the landscape of custom apparel and what it means for businesses and consumers alike.

The world of apparel printing is embracing a new dawn with what is commonly referred to as direct-to-film technology. This modern method allows for intricate designs to be printed directly onto film, making it an ideal choice for creating unique clothing items that cater to personal preferences. Unlike traditional printing techniques, this innovative option provides high-resolution outputs on a variety of materials, from cotton to synthetic blends, ensuring that your custom apparel stands out in a crowded market. As businesses pivot to offer personalized garments, understanding the nuances of this apparel printing technology becomes essential. In this discussion, we will dive deeper into how this advancement is transforming the custom clothing landscape.

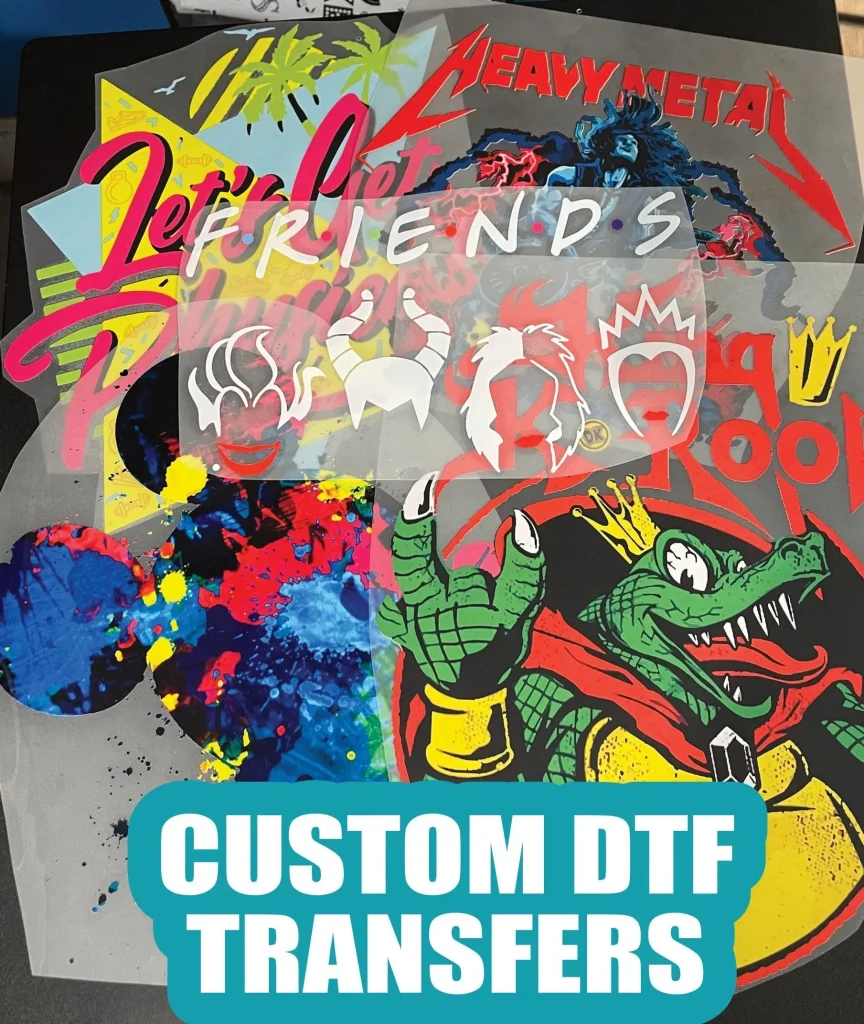

The Power of DTF Transfers in Custom Apparel Printing

DTF transfers have emerged as a game-changer in the world of custom apparel printing, offering unmatched versatility and quality. This printing technique allows for the production of vibrant and detailed designs across various fabric types, from cotton to synthetic blends. The key advantage of DTF transfers lies in their ability to adhere seamlessly to different materials, expanding the horizons for designers and businesses alike. As the demand for personalized apparel continues to rise, DTF technology provides the perfect solution for creating unique pieces that resonate with consumers.

Furthermore, DTF transfers distinguish themselves from traditional printing methods by allowing intricate designs to be produced with ease. Designers can experiment with colors and patterns without worrying about the limitations imposed by other techniques, such as screen printing. The result is a dynamic apparel landscape where uniqueness and creativity take center stage, offering consumers a chance to wear something truly one-of-a-kind.

Understanding the DTF Printing Process

The DTF printing process involves several crucial steps that set it apart from conventional methods. Initially, designs are printed onto specialized films using high-quality inks. These films, once printed, are then transferred onto the fabric using heat and pressure, resulting in a durable and vibrant print. This method not only ensures that the designs retain their clarity but also expands the range of materials that can be printed on, making DTF an attractive option for businesses looking to diversify their product offerings.

Additionally, the user-friendly nature of the DTF printing process allows for a smooth transition for businesses stepping into the world of custom apparel. As even novices can quickly learn the ins and outs of DTF printing, the barrier for entry into the custom clothing market becomes lower, enabling small businesses and independent creators to thrive and express their artistic visions.

DTF vs. Traditional Printing Methods

When comparing DTF printing to traditional methods, such as screen printing, the differences in quality, efficiency, and versatility become clear. Traditional printing often requires extensive setup and multiple screens for different colors, which can lead to increased costs and time delays. In contrast, DTF printing simplifies the process, allowing multiple colors to be printed in one go, thereby reducing production times and costs significantly.

Moreover, DTF technology provides superior print quality, especially when it comes to detailed designs and vibrant colors. The printing directly onto the film means that intricate designs are preserved without losing definition, unlike some traditional methods that might struggle with fine details. This capability to produce high-quality, striking designs is vital in today’s market, where consumers seek unique apparel that sets them apart.

Emerging Trends in Custom Apparel Preferences

Consumer preferences in the custom apparel market are rapidly evolving, with an increasing focus on personalization and distinctiveness. Modern consumers desire apparel that reflects their individuality and often look for brands that can offer customized solutions. DTF transfer technology caters to this demand effectively, providing businesses with the tools needed to produce unique, high-quality designs that resonate with consumers’ personal styles.

Furthermore, as sustainability becomes a paramount concern for many, the eco-friendly nature of DTF printing—with its water-based inks and minimal waste—adds another layer of appeal. Consumers are increasingly aligning their purchasing decisions with brands that prioritize environmental responsibility, making DTF a favorable choice in the competitive landscape of custom apparel.

The Role of DTF Transfers in Small Business Growth

The democratization of the apparel printing industry through DTF technology plays a significant role in empowering small businesses. Unlike traditional printing methods that often require substantial upfront investment in equipment and materials, DTF printing allows small businesses to enter the market without exorbitant costs. This accessibility enables entrepreneurs to innovate and create unique products that cater to niche markets, allowing them to stand out.

As more small businesses utilize DTF transfers for custom apparel, they can offer a wider variety of personalized products that meet the specific needs of individual consumers. This flexibility not only helps small businesses grow but also fosters competition and diversity within the market, leading to a richer landscape of apparel choices for consumers.

Future Innovations in DTF Printing Technology

The future of DTF printing technology is promising, with continuous advancements poised to enhance the capabilities of this already powerful method. Ongoing developments in printing equipment and ink formulations are set to improve adhesion, durability, and the overall quality of transfers. As these innovations arise, they will likely further lower production costs and streamline the printing process, making DTF an even more attractive option for businesses of all sizes.

Moreover, emerging trends in automation and digital integration in DTF processes are expected to reshape the production landscape. As technology evolves, suppliers and businesses will likely benefit from faster turnaround times and the ability to implement more complex designs, positioning DTF printing as a leading choice in the ongoing evolution of custom apparel printing.

Frequently Asked Questions

What are DTF transfers and how do they work in custom apparel printing?

DTF transfers, or Direct-to-Film transfers, involve printing designs onto a special film which is then heat-transferred onto various fabrics. This innovative apparel printing technology allows for vibrant colors and high detail in custom apparel, making it suitable for diverse materials like cotton and polyester.

How does DTF printing compare to traditional printing methods for personalized apparel?

DTF printing stands out from traditional techniques by offering enhanced versatility and print quality. Unlike methods like screen printing, DTF transfers can adhere to a broader range of fabrics, allowing for unique and high-quality personalized apparel without significant financial investment.

What recent advancements have been made in DTF transfer technology?

Recent advancements in DTF transfer technology include improved printers and films that enhance adhesion and durability. These innovations make the printing process quicker and more accessible, encouraging more businesses to enter the custom apparel market with ease.

Why is DTF printing considered eco-friendly for custom apparel?

DTF printing is considered eco-friendly due to the use of water-based inks in many DTF products, which are less harmful to the environment. This aligns with the increasing consumer demand for sustainable practices in the apparel industry.

How is the DTF transfer market expected to grow in the coming years?

The DTF transfer market is projected to exceed $1 billion by 2030, driven by the rising popularity of personalized apparel. The technology’s affordability and efficiency have made it appealing to small businesses and start-ups, fueling market growth.

Why do consumers prefer custom apparel printed with DTF technology?

Consumers prefer custom apparel printed with DTF technology due to its ability to produce vivid designs and personalized prints that resonate with individual identities. Additionally, the eco-friendly aspects of DTF align with growing consumer preferences for sustainable fashion.

| Key Features of DTF Transfers | Description | |

|---|---|---|

| High Print Quality | DTF printing ensures vibrant colors and sharp imagery, preserving details during transfer. | |

| Versatility | Works on various fabric types, including cotton, polyester, and blends, catering to diverse consumer needs. | |

| Cost-Effectiveness | Lower production costs make it accessible for small to medium businesses. | |

| Eco-Friendly Approach | Utilizes water-based inks, contributing to sustainable practices. | |

Summary

DTF transfers are revolutionizing custom apparel printing by offering a unique blend of high print quality, versatility, cost-effectiveness, and eco-friendliness. This innovative printing method has made it easier for businesses of all sizes to create personalized apparel that meets the evolving demands of consumers. As the trend toward customization continues to rise, DTF technology empowers brands to offer distinctive designs that resonate with individual identities while also addressing environmental concerns. The future of custom apparel is undoubtedly bright, with DTF transfers at the forefront of this exciting transformation.