DTF transfers, or Direct-to-Film transfers, are revolutionizing the world of custom T-shirt design with their cutting-edge technology. By enabling the printing of vibrant and intricate designs onto films, DTF printing stands out as a superior option for apparel decoration. As companies strive to deliver high-quality and eco-friendly apparel, DTF transfers provide a resolving solution that meets consumer demands for sustainability. This innovative method not only outperforms traditional screen printing in quality but also offers remarkable cost-effectiveness and material versatility. In this article, we will explore the numerous DTF printing benefits that make it a leading choice for businesses looking to enhance their custom T-shirt offerings.

Alternative terms like Direct-to-Film printing highlight the transformative nature of this technology in the garment industry, providing a modern twist on custom T-shirt creation. With its seamless process, DTF transfers allow designers to apply detailed graphics onto fabrics efficiently, making it a preferred screen printing alternative. As enthusiasts seek out unique and personalized apparel, embracing DTF technology ensures that designers can cater to diverse customer preferences while meeting the growing trend for eco-friendly practices. Additionally, the quality and adaptability offered by DTF printing serve to redefine industry standards and broaden the potential for creative expression in fashion. Undoubtedly, the rise of this printing method is setting a new benchmark for the future of apparel design.

Understanding DTF Transfers and Their Functionality

DTF transfers, or Direct-to-Film transfers, represent a cutting-edge approach to custom T-shirt design that merges technology with creativity. This innovative method involves printing high-resolution images onto a specially designed transfer film, which is then applied to the fabric using heat. This process not only allows for vibrant colors and detailed graphics but also provides an efficient way to produce custom apparel in various sizes and styles. The versatility of DTF transfers has made them a popular choice for both small businesses and large manufacturing companies alike, as they cater to a wide range of customer preferences.

Moreover, the DTF process is user-friendly and quick, allowing designers to produce high-quality custom designs in less time. Unlike traditional screen printing, which requires multiple steps and significant setup, DTF printing involves a streamlined approach that minimizes complications. This efficiency enables businesses to respond rapidly to market trends and customer demands, making it an advantageous choice in the fast-paced fashion industry.

Benefits of DTF Printing in Custom T-Shirt Design

The benefits of DTF printing extend beyond mere efficiency; they also encompass quality and versatility. DTF transfers can produce stunningly detailed prints that rival those generated by screen printing. The advanced printing technology ensures that colors remain vibrant and true to their original design, making them ideal for intricate designs and even photographic quality artwork. As businesses continue to prioritize quality in their offerings, the ability to deliver exceptional prints using DTF technology sets custom apparel providers apart from their competitors.

Additionally, DTF printing allows for greater material versatility. This process can be applied to a wide range of fabrics, including cotton, polyester, and blends, making it suitable for a multitude of apparel types, from sportswear to fashion garments. This adaptability not only broadens market reach but also aligns with changing consumer preferences for various styles and materials in the ever-evolving fashion landscape.

Eco-Friendly Practices in DTF Transfers

With an increasing emphasis on sustainability in the fashion industry, DTF transfers present a compelling eco-friendly alternative to traditional printing methods. DTF technology predominantly uses water-based inks, which significantly reduce the reliance on harmful solvent-based inks associated with other printing methods such as screen printing. This reduction in harmful substances not only makes for a safer working environment but also resonates with consumers who are becoming more conscious of the environmental impact of their clothing choices.

As customer demand shifts towards eco-friendly apparel, companies implementing DTF technology can position themselves as leaders in sustainable fashion. By offering products that minimize environmental footprints and utilize sustainable practices, businesses can attract a growing base of conscientious consumers who prioritize ethical production. This commitment to eco-friendliness can bolster brand loyalty and increase sales in an increasingly competitive market.

DTF vs. Traditional Screen Printing: A Comparative Analysis

When comparing DTF transfers to traditional screen printing, several key differences emerge, particularly regarding cost and production speed. DTF printing eliminates the extensive setup costs associated with screen printing processes, such as creating and maintaining multiple screens. This cost-effectiveness makes DTF a more viable option for small businesses engaging in low-volume or custom designs, as they can significantly reduce overhead costs and enhance profit margins.

Furthermore, DTF transfers offer quicker production times than traditional methods. The streamlined process of printing directly onto film and subsequently transferring it onto fabric allows brands to fulfill orders much faster. This ability to meet tight deadlines can be a game-changer for custom apparel providers, especially when catering to fast-paced trends or immediate consumer demands.

Navigating the DTF Printing Process: Steps and Tips

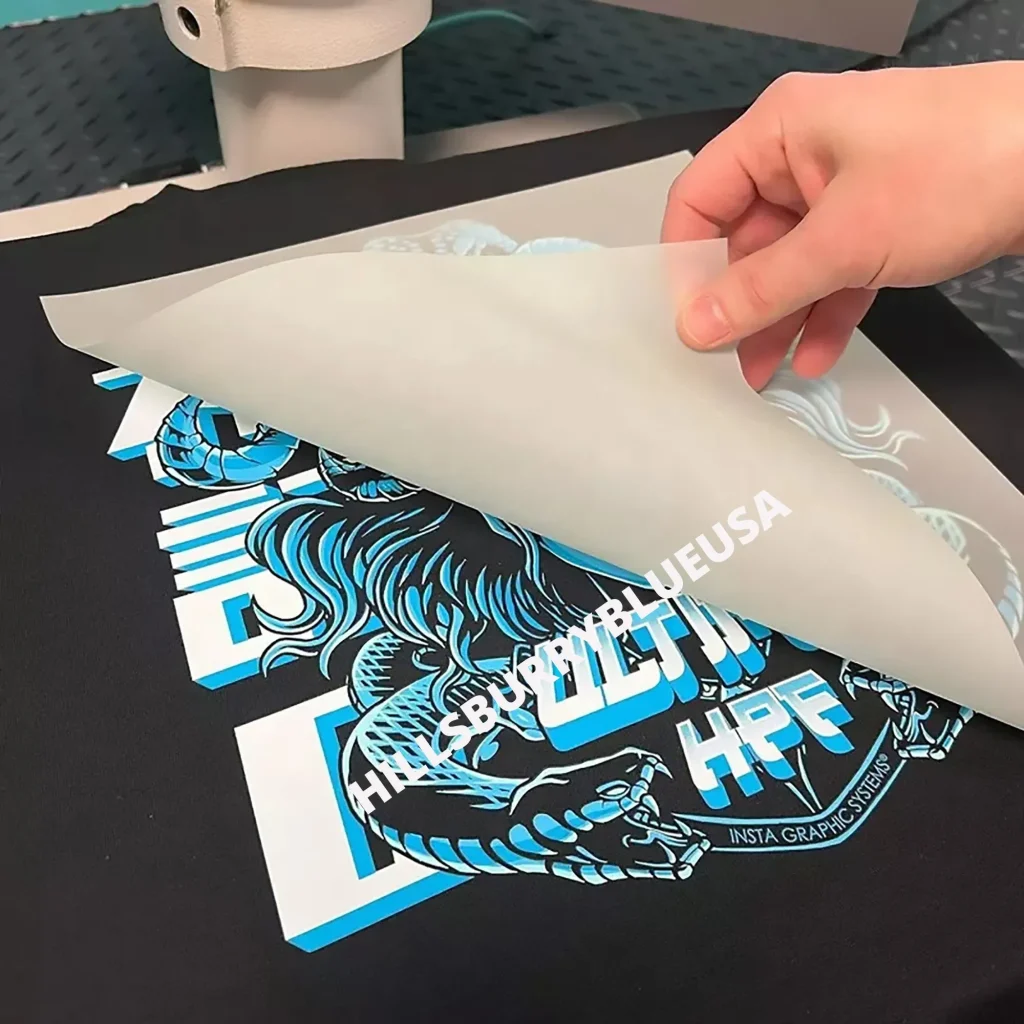

Navigating the DTF printing process can be straightforward with a basic understanding of the steps involved. First, a design is created and printed onto special transfer film. This initial step is crucial, as the quality of the print will directly affect the final outcome on the fabric. After printing, an adhesive powder is applied to the film, which will help bond the ink to the garment during the heat transfer process. Following these preparations, the film is pressed onto the fabric using a heat press, solidifying the design in a matter of seconds.

For optimal results, it’s essential to pay attention to temperature and pressure settings during the heat transfer stage. Different fabrics may require specific adjustments to ensure that the DTF transfer adheres properly without damaging the material. As users become familiar with these nuances, they can consistently produce high-quality custom T-shirts that meet customer expectations.

The Future of DTF Transfers in the Apparel Industry

The future of DTF transfers appears bright and promising as technology continues to evolve and advance. Ongoing innovations may lead to faster printing speeds and improved ink formulations, further enhancing the quality and efficiency of DTF printing. Businesses that invest in staying updated with these advancements will likely gain a competitive edge in the rapidly changing apparel market, continuously attracting diverse customer bases looking for high-quality custom clothing.

Furthermore, as consumer preferences gravitate toward personalization and sustainability, DTF transfers align perfectly with these demands. By leveraging this technology, businesses can offer tailored designs while also affirming their commitment to environmentally responsible practices. The fusion of customization, quality, and sustainability positions DTF printing at the forefront of the future of T-shirt design, reshaping the landscape of custom apparel.

Frequently Asked Questions

What are DTF Transfers in custom T-shirt design?

DTF Transfers, or Direct-to-Film printing, is a modern technique used in custom T-shirt design where images are printed onto a special film, which is then transferred onto fabrics. This method is celebrated for its ability to produce vibrant and detailed designs on various materials.

How do DTF Printing benefits compare to traditional screen printing?

DTF Printing benefits include lower setup costs, faster production times, and reduced waste, making it a cost-effective alternative to traditional screen printing. Unlike screen printing, DTF technology also allows for high-quality prints with intricate details, which enhances customer satisfaction.

Is DTF Transfers technology eco-friendly?

Yes, DTF Transfers utilize water-based inks, making them a more eco-friendly option compared to traditional screen printing, which often uses solvent-based inks. This sustainable approach not only lowers environmental impact but also promotes healthier conditions for both workers and consumers.

What types of fabrics can DTF Transfers be used on?

DTF Transfers are versatile and can be applied to a wide range of fabrics, including cotton, polyester, and their blends. This compatibility allows businesses to cater to different apparel niches such as sportswear, casual wear, and promotional items.

What makes DTF Transfers easier to use than other printing methods?

The DTF printing process is streamlined and straightforward, involving printing designs onto a film, applying adhesive, and using a heat press to transfer images to garments. This ease of use enables quick and efficient production, perfect for custom apparel demands.

What is the future of DTF Transfers in the apparel industry?

The future of DTF Transfers looks promising as the technology continues to expand in popularity across the apparel sector. We can expect advancements like faster printing speeds, improved ink formulations, and broader material compatibility, further solidifying DTF technology as a leader in custom T-shirt design.

| Key Point | Description |

|---|---|

| Introduction to DTF Transfers | Innovative technology allowing high-quality images to be transferred onto fabrics, revolutionizing custom apparel. |

| Cost-Effectiveness | Eliminates setup costs of traditional printing, reduces waste, ideal for small batches and on-demand printing. |

| Quality of DTF Prints | Produces vibrant colors and intricate details, ensuring high-quality products that satisfy customers. |

| Material Versatility | Compatible with various fabrics including cotton and polyester, catering to diverse fashion niches. |

| Ease of Use | Straightforward process involving printing on film, applying adhesive, and heat pressing, streamlining production. |

| Environmental Impact | Uses water-based inks, reducing environmental footprint and aligning with consumer demand for sustainability. |

| Industry Adoption and Future Trends | Fast adoption across sectors with ongoing innovations, like quicker printing speeds and improved ink formulations. |

Summary

DTF Transfers are revolutionizing T-shirt design by offering a more efficient and versatile approach to creating custom apparel. This innovative technology not only enhances print quality and material compatibility but also significantly reduces costs associated with traditional printing methods. As sustainability becomes increasingly important, the use of DTF transfers helps to meet consumer demand for eco-friendly products, making this method not only cost-effective but also responsible. By harnessing the power of DTF printing, businesses can distinguish themselves in a competitive market while contributing to a more sustainable future in the fashion industry.