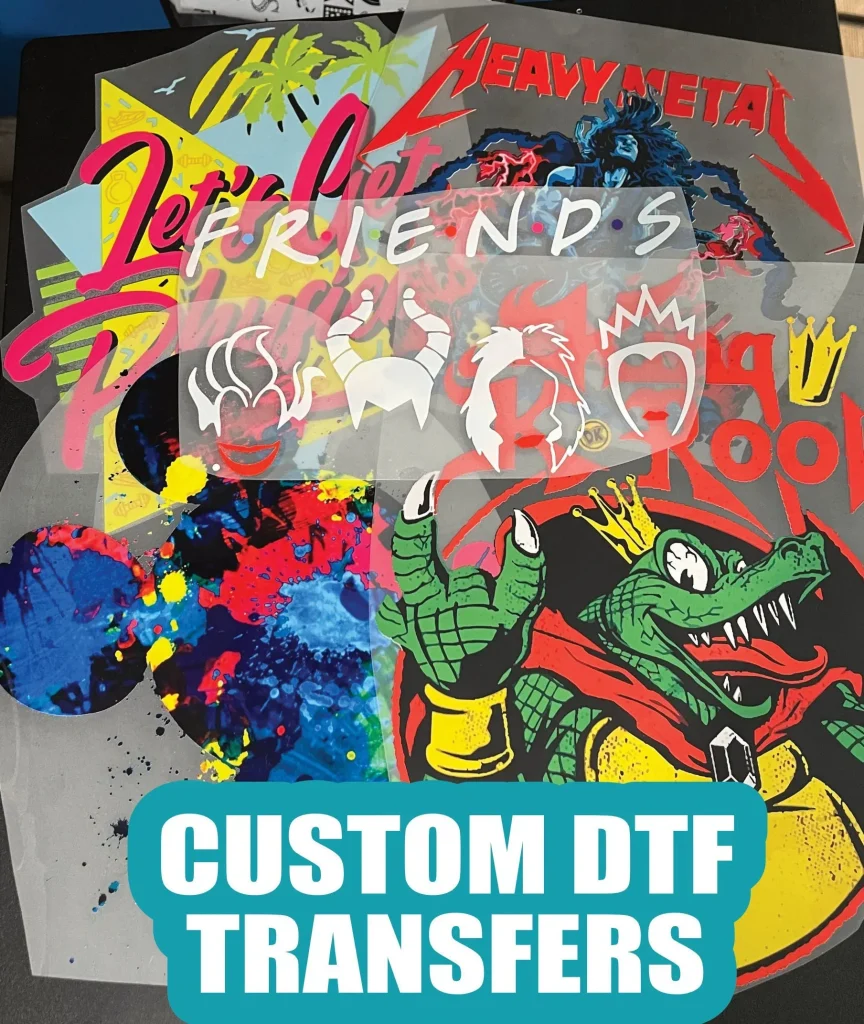

DTF transfers, or Direct-to-Film transfers, are transforming the landscape of custom apparel with their innovative printing technology. This advanced method allows artists and entrepreneurs to create stunning designs that burst with color and detail, making it a top choice for both small businesses and hobbyists alike. By using DTF printing technology, you can achieve high-quality custom DTF transfers that rival traditional methods in vibrancy and durability. In this guide, we’ll explore essential heat transfer methods, provide tips on selecting the right DTF design templates, and outline the steps needed to bring your creative visions to life. Whether you’re a seasoned designer or just starting out, understanding DTF transfers is key to your success in the world of custom designs.

The realm of apparel decoration has been greatly enhanced by the advent of film-based transfer techniques. Known as Direct-to-Film (DTF) printing, this modern approach enables users to apply intricate designs onto various fabric surfaces with impressive clarity and durability. By leveraging custom DTF applications, designers can explore a wide array of creative possibilities, ensuring that each print meets their unique vision. As we dive deeper into the process, we will cover everything from the latest heat application methods to utilizing pre-made DTF design templates, helping you navigate the exciting world of custom imprinting.

The Advantages of DTF Transfers in Custom Printing

When it comes to custom printing, DTF transfers have emerged as a formidable alternative to traditional methods. One of the most significant advantages of DTF printing technology is its ability to produce vibrant colors with impressive detail. Unlike traditional screen printing, which can be limited when it comes to color gradients, DTF transfers allow for an endless array of hues, making them ideal for intricate designs and patterns. This versatility is particularly beneficial for small businesses and independent creators who want to offer unique and eye-catching products.

Moreover, the durability of DTF transfers cannot be overstated. Once applied correctly using heat transfer methods, these prints maintain their vibrancy even after multiple washes. They are resistant to cracking and peeling, which can often plague other printing methods. As a result, apparel made with DTF transfers provides a long-lasting solution for custom printing, ensuring customer satisfaction and repeat business. This combination of quality, durability, and ease of application makes DTF transfers a preferred choice for many in the custom apparel industry.

Essential Tools for DTF Transfer Printing

To harness the full potential of DTF printing, it is crucial to gather the right tools before embarking on your design journey. Primarily, a dedicated DTF printer is necessary, as it ensures that the inks used are compatible and optimized for this technique. Alongside the printer, you will need DTF transfer films that will serve as the medium onto which your designs are printed. Using the correct film is vital to achieve the desired transfer quality and durability.

In addition to the printing equipment, a heat press is indispensable for applying DTF transfers flawlessly to your chosen fabrics. This device allows for precise temperature and pressure control, which is essential for a successful transfer. Furthermore, graphic design software such as Adobe Illustrator or CorelDRAW plays a pivotal role in creating high-resolution images that can leverage the advantages of DTF technology. By investing in these tools, you’ll lay a solid foundation for creating professional-grade prints that stand out in a crowded market.

Creating Stunning DTF Design Templates

Designing custom DTF transfers begins with the creation of high-quality design templates. This process typically starts by conceptualizing your artistic vision and translating it into a digital format. When creating DTF design templates, it’s important to consider the type of fabric and the intended use of the finished product. For instance, intricate designs may require larger printing areas and careful color selections to maintain clarity and vibrancy on the garment.

Additionally, utilizing design templates tailored specifically for DTF printing can streamline the creation process. Many software programs offer pre-made templates that are optimized for this technology, allowing users to input their designs easily. These resources save time and ensure that technical specifications such as DPI and color profiles are correctly set, leading to higher quality final products. By carefully crafting your design templates, you can enhance productivity while maintaining a high level of creativity.

Step-by-Step Process for Printing DTF Transfers

The step-by-step process for printing DTF transfers is essential for achieving great results. Begin by preparing your design in graphic design software, ensuring that it is high resolution and appropriately colored for the fabric. Once your design is ready, it’s time to print. Adjust your DTF printer settings according to the manufacturer’s guidelines to optimize ink usage and print quality. It’s crucial to use the right kind of transfer film, as it directly impacts the clarity and durability of the final product.

After printing, allow the transfer to dry completely, which prevents smudging during the transfer process. When you’re ready to apply the DTF transfer to fabric, preheat your heat press and carefully position your design. Follow manufacturer instructions regarding the pressing duration and temperature for the best results. By meticulously following these steps, you’ll not only ensure a successful transfer but also enhance the overall quality of your custom prints.

Tips for Successful DTF Transfer Application

Applying DTF transfers effectively is a skill that can be honed with practice and attention to detail. One primary tip for successful application is to ensure your heat press is correctly calibrated. The right temperature and pressure can make all the difference in how well the transfer adheres to the fabric. Additionally, preheating the fabric before applying the transfer helps remove any moisture and promotes a better bond between the transfer and the textile.

Furthermore, it’s beneficial to perform a test application before committing to your final product. This allows you to assess how the design reacts to heat and adheres to the fabric, ensuring that there are no surprises with the final output. Additionally, always allow the transfer to cool appropriately before peeling away the film to prevent any premature damage. Consistently applying these tips will enhance your success rates in producing high-quality custom DTF prints.

Exploring Innovations in DTF Printing Technology

The field of DTF printing technology is continuously evolving, with recent innovations enhancing performance and quality. One standout advancement is Insta DTF, which focuses on providing users with a more versatile approach to app dress decoration. This system not only boosts color vibrancy but also enhances the durability of prints, making it a favorable choice for both large-scale and small business operations.

Moreover, services like Sam’s DTF Transfers cater to a wide range of brands, offering custom DTF transfers without strict minimum order requirements. This flexibility allows businesses of all sizes to take advantage of high-quality printing solutions. Staying informed about such innovations in DTF technology not only informs your business decisions but also inspires creativity in your design processes, ensuring that you remain competitive in the market.

Frequently Asked Questions

What are DTF transfers and how do they work in custom printing?

DTF transfers, or Direct-to-Film transfers, utilize a specialized printing process to apply vibrant designs onto fabrics. This method allows for high-resolution images to be printed on a film, which is then heat pressed onto the desired textile, resulting in durable and vivid designs.

How do I choose the right DTF printing technology for my needs?

When selecting DTF printing technology, consider factors like the printer’s compatibility with DTF transfer films, the quality of prints it produces, and any additional features like speed or ease of use. Research options like Insta DTF or Sam’s DTF Transfers that cater to different printing requirements.

What are the best practices for creating custom DTF transfers?

To create effective custom DTF transfers, use high-resolution images (minimum 300 DPI), select complementary colors to enhance contrast, and test your designs through several prints before finalizing. This ensures quality and vibrancy in the final product.

How do DTF transfers compare to other heat transfer methods?

DTF transfers offer several advantages over traditional heat transfer methods, such as sublimation. They allow for more intricate designs and a broader color palette, resulting in more vibrant and durable prints that can adhere well to various fabric types.

Can I use DTF design templates for my projects?

Yes, DTF design templates are a great resource for creators looking to streamline their design process. These templates are specifically optimized for DTF printing and can save time, ensuring that your artwork meets the required specifications for high-quality transfers.

What equipment do I need to start with DTF printing?

To start with DTF printing, you’ll need a compatible DTF printer, DTF transfer films, a heat press for applying the transfers, and graphic design software like Adobe Illustrator or CorelDRAW for designing your prints.

| Key Points | Details |

|---|---|

| DTF Transfers | Method of applying designs onto fabrics using a special film for vibrant and durable prints. |

| Critical Equipment | DTF printer, compatible transfer films, heat press, and graphic design software (e.g., Adobe Illustrator). |

| Major Innovations | Insta DTF and Sam’s DTF Transfers have enhanced customization options and efficiency for users. |

| Step-by-Step Creation Process | 1. Gather Equipment 2. Design Techniques 3. Print Transfers 4. Apply Transfers 5. Quality Checks |

| Comparison with Sublimation | DTF allows for more intricate designs and colors compared to sublimation methods. |

| Conclusion | DTF transfers have changed the game for custom printing, allowing anyone to create bold and lasting designs with the right techniques and tools. |

Summary

DTF transfers have transformed the landscape of custom printing, enabling designers to produce eye-catching and high-quality designs with remarkable ease. By mastering the techniques and using top-notch innovations such as Insta DTF and Sam’s DTF Transfers, anyone can unleash their creativity and produce apparel that stands out. This comprehensive guide arms you with the essential knowledge and steps needed to embark on a successful DTF printing journey, emphasizing a blend of technical proficiency and artistic flair. Stay updated with the latest trends and methods in DTF transfers to continuously elevate your craft and resonate with your audience.