DTF transfer paper is revolutionizing the way we print designs onto fabric, making it easier than ever to achieve vibrant and professional results. Whether you’re a DIY enthusiast or a seasoned printer, knowing how to choose DTF transfer paper can significantly impact your project’s outcome. When selecting the best DTF transfer paper, factors such as paper quality, printer compatibility, and adhesive properties should be at the forefront of your decision-making process. In this guide, we will share valuable DTF printing tips to help you navigate the options available and ensure perfect prints every time. Get ready to learn how to use DTF transfer paper effectively and unlock endless creative possibilities for customizing various fabrics!

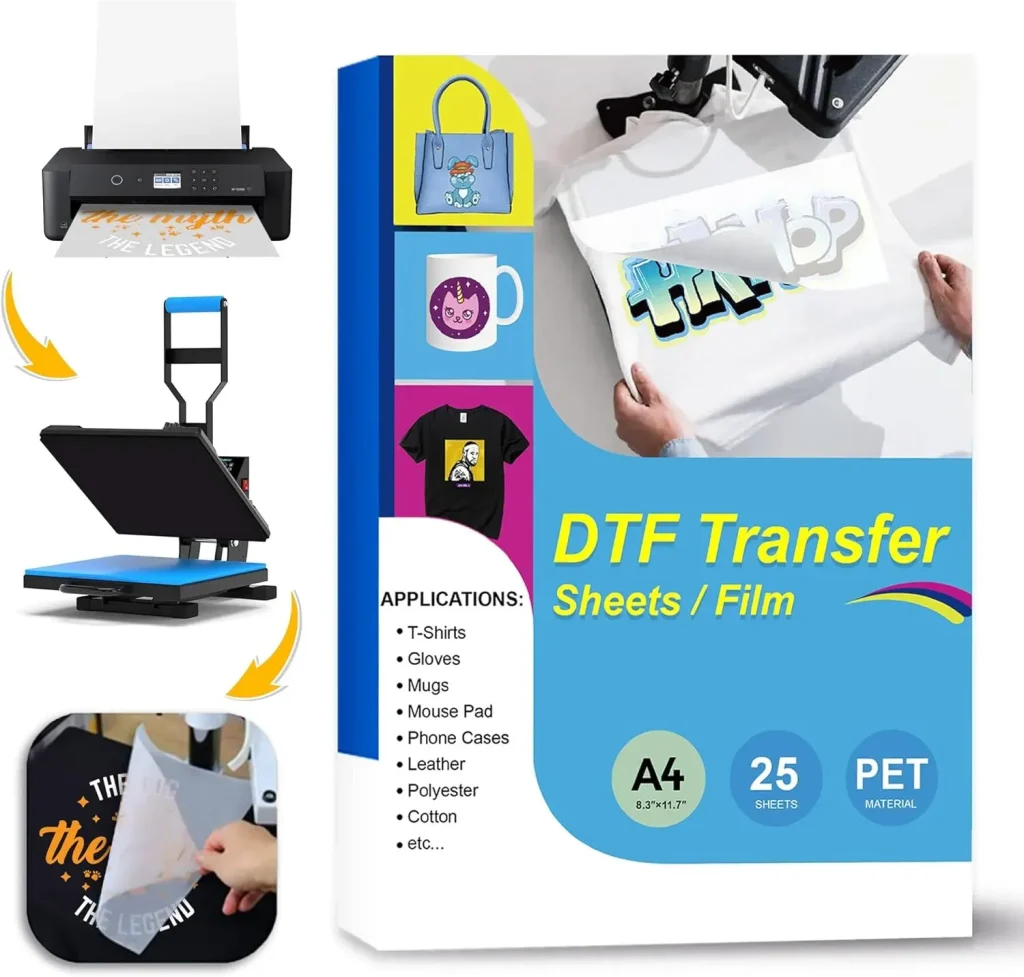

Direct-to-Film (DTF) transfer paper has emerged as a game-changing solution for fabric printing, allowing users to easily create high-quality designs with minimal hassle. This innovative approach, often termed film printing, enables the application of intricate graphics onto different textile surfaces, catering to both hobbyists and commercial enterprises alike. Understanding the nuances of selecting the ideal transfer material is essential for achieving vibrant colors and precise detailing in your projects. By exploring the fundamentals of this technology, including evaluating printing essentials and determining the suitable paper thickness, you can ensure that your projects stand out. Join us as we delve into the essential steps to successfully navigate the world of transfer papers and elevate your fabric printing endeavors to new heights.

Key Features to Look for in DTF Transfer Paper

When selecting DTF transfer paper, several key features can affect the quality of your final prints. The first important aspect is the paper’s opacity. A high-opacity transfer paper prevents the base color of the fabric from affecting the vibrancy of your printed design, ensuring that colors pop and details remain sharp. Furthermore, the texture of the transfer paper also plays a crucial role in the final outcome. A smooth, well-finished surface aids in better ink transfer and adhesion, which is essential for achieving professional-looking results.

Durability is another critical factor when choosing DTF transfer paper, as it needs to withstand the heat and pressure of the heat press without curling or warping. Papers designed for durability will also stand up better to washing and everyday wear, maintaining the original appearance of your transferred designs over time. Therefore, investing in high-quality features ensures that your prints not only look great but also last long on the fabric surfaces.

Understanding Printer Compatibility with DTF Transfer Paper

Printer compatibility is a vital consideration when choosing DTF transfer paper, as not all types of transfer paper work seamlessly with every printer. It’s important to know whether your printer uses water-based, solvent-based, or pigment inks, as this determines the type of transfer paper that will yield optimal results. Manufacturers often specify the types of printers that their DTF transfer papers are compatible with, so always check these recommendations before making a purchase.

Failing to consider printer compatibility might lead to undesirable outcomes, such as incomplete transfers or poor image quality. Choosing the right DTF transfer paper that aligns with your ink technology not only enhances print quality but can also streamline the overall transfer process, allowing for a smoother user experience during your printing projects.

Frequently Asked Questions

How do I choose the best DTF transfer paper for my projects?

Choosing the best DTF transfer paper involves assessing the paper’s quality, thickness, adhesive properties, and compatibility with your printer. Look for high opacity, smooth texture, and durability to ensure vibrant prints and ease of use.

What are essential DTF printing tips for beginners using DTF transfer paper?

For beginners, essential DTF printing tips include ensuring printer compatibility with the paper, adhering to recommended heat press settings, and testing small samples before committing to large projects. This will help achieve optimal results.

What types of fabrics are best suited for DTF transfer paper?

DTF transfer paper works well with a variety of fabrics, including cotton, polyester, and mixed fabrics. Choosing the right adhesive type on the paper ensures the best bonding and print longevity, depending on the fabric composition.

How do I use DTF transfer paper effectively in my printing projects?

To effectively use DTF transfer paper, print your design on the paper, let it dry as per instructions, then heat press it onto your fabric at the appropriate temperature and time settings for optimal transfer.

Can I use DTF transfer paper with any printer?

Not all printers are compatible with DTF transfer paper. It’s vital to check that your printer can use water-based or solvent-based inks suited for DTF printing, following manufacturer recommendations for the best results.

What should I consider regarding heat press settings when using DTF transfer paper?

When using DTF transfer paper, consider the recommended heat press settings, including temperature and pressing time, as these can vary by paper brand. Ensuring your heat press can accommodate these settings is crucial for successful transfers.

| Key Aspect | Details |

|---|---|

| Quality of Paper | Look for high opacity, smooth texture, and durability to prevent print quality issues. |

| Printer Compatibility | Ensure the paper is compatible with your specific printer and ink type. |

| Paper Thickness and Weight | Heavier papers can improve transfer quality, but check printer capability. |

| Adhesive Properties | Select suitable adhesives based on fabric types, such as cotton or polyester. |

| Heat Press Settings | Research specific temperature and time settings for optimal transfer. |

| Purpose of Use | Consider the end use and frequency of washing to determine paper type. |

| Reputable Brands | Opt for trusted brands to ensure quality and good customer support. |

Summary

DTF transfer paper is crucial for achieving high-quality prints in your textile projects. Selecting the right DTF transfer paper involves assessing factors like paper quality, printer compatibility, thickness, adhesive properties, and the specific requirements of your project. Understanding these elements helps ensure vibrant designs that withstand everyday wear and washing. Experimenting with different brands can lead to the perfect match for your creative endeavors, enhancing both the quality of your prints and customer satisfaction. Happy printing!