DTF printing, or Direct-to-Film printing, has rapidly gained attention as a revolutionary technique in the world of textile printing. This innovative method offers the unique ability to produce high-quality prints that are not only vibrant but also incredibly durable, making it a top choice for custom apparel. The versatility of DTF allows it to work seamlessly on a wide range of fabrics, from cotton to polyester, catering to various printing needs. With an easy application process that involves straightforward transfer using heat, DTF printing is accessible for both professional businesses and enthusiastic hobbyists. In this article, we will explore the numerous advantages of DTF printing, showcasing why it has become a popular solution for creative and commercial projects alike.

In the realm of fabric printing, Direct-to-Film (DTF) techniques have transformed the landscape by enabling high-resolution graphics transfer onto textiles. Often referred to as film transfer printing, this approach combines simplicity with exceptional print quality, ensuring that even the most intricate designs are rendered with stunning detail. The adaptable nature of this method means it can be applied across various fabrics, making it a favored choice for anyone looking to create custom apparel or promotional items. Thanks to the straightforward application procedure, even newcomers to the garment printing world find it easy to achieve professional results. As we delve deeper into the benefits and capabilities of this printing technology, the potential for creativity and efficiency in the custom printing market will become clear.

The Advantages of High-Quality Prints with DTF Printing

DTF printing is renowned for producing high-quality prints that stand out in the crowded apparel market. Unlike traditional screen printing methods that may struggle with complex and colorful designs, DTF allows for vibrant graphics to be transferred onto various fabrics with remarkable clarity. The prints yield vivid colors and fine details that are resistant to fading, ensuring that the designs maintain their aesthetic appeal even after numerous washes. Thus, businesses and creators are drawn to DTF as a means of elevating their products without compromising on quality.

Moreover, the bubble formation during the DTF transfer process acts as a protective layer that enhances the print’s durability. This results in not just visually striking designs but also fabrics that can withstand wear and tear over time. The longevity of high-quality prints is especially crucial for custom apparel, where consumers demand both aesthetic beauty and practical usability. By leveraging DTF printing, businesses can offer garments that appeal to style-conscious customers while ensuring they get excellent value for their investment.

Exploring the Versatility of DTF Printing

The versatility of DTF printing is one of its standout features, enabling it to cater to a wide array of applications. From custom t-shirts and hoodies to promotional products and accessories, the adaptability of DTF printing meets the diverse needs of creators and businesses alike. This flexibility allows for the easy application of designs to various materials including cotton, polyester, and fabric blends, giving users the freedom to experiment with different textures and styles. Whether the project requires a simple logo or an intricate graphic, DTF can handle it all.

In addition, the ability to print on unconventional items such as tote bags or caps demonstrates the breadth of DTF’s usability. The compatibility with multiple substrates expands the horizons for creative projects, leading to innovative business opportunities, particularly in industries where personalized merchandise is in high demand. Thus, DTF printing not only enhances custom apparel creation but also encourages artistic exploration across various product lines, benefiting both businesses and consumers.

Step-by-Step Guide to Easy Application of DTF Prints

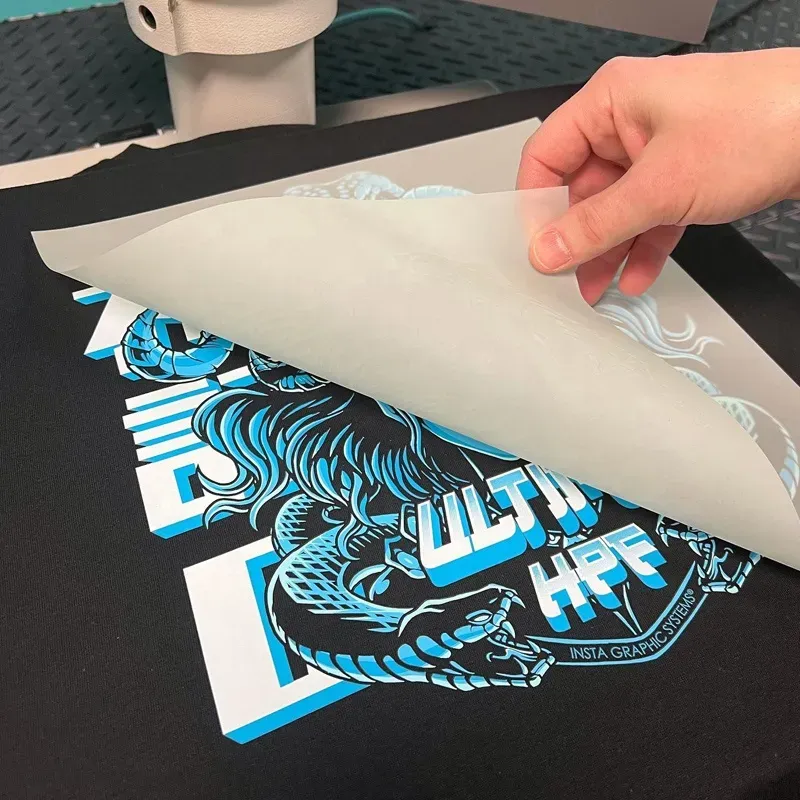

Applying DTF prints is designed to be an accessible process, which is one of the primary reasons for its growing popularity. The method is overwhelmingly straightforward, primarily requiring a heat press for the application. Users simply need to prepare their project by printing the design onto the film, cutting it to the desired shape, and then applying heat and pressure to transfer the image onto the fabric. This simplicity makes it an appealing option for small business owners, hobbyists, and even those new to the world of custom printing.

This ease of application allows individuals to produce high-quality prints without extensive training or specialized equipment. Many find that they can achieve professional-grade results in a relatively short amount of time, which helps boost productivity and fosters confidence in their printing capabilities. For budding entrepreneurs or enthusiasts, DTF printing democratizes the ability to delve into custom apparel projects with minimal barriers to entry.

Cost-Effectiveness: Why DTF Printing Fits Any Budget

One of the key draws of DTF printing is its cost-effectiveness, making it suitable for various budgets, from small startups to larger enterprises. The materials required for DTF—such as films and special inks—are competitively priced, allowing businesses to manage their operational costs while providing high-quality products. This aspect is particularly beneficial for print-on-demand businesses that require small runs, as DTF printing offers a feasible way to meet customer demands without inflating costs unnecessarily.

Moreover, the absence of prerequisites like garment pre-treatment enhances the cost-efficiency of DTF printing. Businesses can reduce their expenditures on labor and materials, thereby maximizing profit margins. This financial advantage helps many small businesses enter the custom printing market, as they can provide competitive pricing while still delivering top-notch products. DTF printing truly represents a strategic choice for those looking to optimize their return on investment without sacrificing quality.

Improving Workflow Efficiency with DTF Technology

DTF printing introduces a welcomed shift in workflow efficiency compared to traditional printing methods. One primary advantage is the elimination of pre-treatment processes which can be labor-intensive and time-consuming. By streamlining the setup and production stages, DTF allows businesses to quickly respond to orders while maintaining high-quality standards, ultimately enhancing productivity. This efficiency is crucial in today’s fast-paced market, where timely delivery can set a business apart from competitors.

Furthermore, the compact nature of DTF printing technology supports lower overhead costs. Businesses can allocate resources more effectively, which is especially beneficial for those in the custom apparel industry who may deal with fluctuating demand. With an efficient workflow facilitated by DTF, print shops and entrepreneurs can focus more on creativity and customer relations, thus driving growth and satisfaction in their operational processes.

Future Developments in DTF Printing Technology

The landscape of DTF printing technology is continually evolving, promising exciting opportunities for businesses and creators looking to push the envelope in custom printing. Recent advancements focus on enhancing design software, allowing for better color management systems and greater compatibility with various materials. As technology progresses, more user-friendly interfaces are becoming available, simplifying the design and printing process for users of all expertise levels.

These developments not only enhance the technical aspects of DTF printing but also democratize access to these advancements. With more intuitive software on the market, new users can seamlessly incorporate DTF printing into their workflows, stimulating creativity and innovation in creating unique apparel and promotional items. As the technology matures, it is set to further solidify DTF printing’s status as a predominant method for custom printing, appealing to both established businesses and those just starting in the industry.

Frequently Asked Questions

What is DTF printing and how does it differ from traditional printing methods?

DTF printing, or Direct-to-Film printing, is a modern technique that transfers designs directly onto fabrics using a specialized film. Unlike traditional methods like screen printing, which may limit intricate designs, DTF printing offers high-quality prints with vibrant colors and sharp details, making it suitable for various materials.

What kinds of materials can DTF printing be applied to?

The versatility of DTF printing allows it to be successfully applied to a variety of materials, including cotton, polyester, and mixed fabrics. This adaptability makes it a preferred choice for custom apparel and promotional items, expanding the possibilities for individual and business applications.

Is DTF printing easy to use for beginners?

Yes, DTF printing offers an easy application process, which involves using a heat press to transfer designs onto fabrics. This makes it accessible for beginners and small business owners, allowing them to create high-quality prints quickly with minimal training.

How does DTF printing compare in terms of cost-effectiveness?

DTF printing is particularly cost-effective for small runs and customized orders, which are common requirements in print-on-demand businesses. The competitive pricing of DTF materials, like films and inks, allows businesses to achieve profitability while maintaining high-quality output.

Can DTF printing produce high-quality prints on dark fabrics?

Absolutely! DTF printing excels at producing high-quality prints on dark fabrics, thanks to its unique printing process. The ink transfer method creates vivid hues and sharp details, ensuring that even complex graphics stand out effectively, regardless of the fabric color.

What are the recent advancements in DTF printing technology?

Recent developments in DTF printing technology include improved design software that enhances color management and compatibility with various materials. These advancements are making the DTF printing process more user-friendly, encouraging a wider range of creators and businesses to explore custom printing options.

| Key Benefit | Description |

|---|---|

| High Print Quality | Produces vibrant colors and sharp details, allowing for intricate designs even on dark fabrics. |

| Versatility | Works on various materials including cotton and polyester, suitable for a wide range of products. |

| Ease of Application | Straightforward heat press application, making it accessible for beginners and small businesses. |

| Cost-Effectiveness | Economical for small runs and customizable orders, competitive pricing on materials. |

| Efficient Workflow | Eliminates the need for pre-treatment, resulting in a faster production process. |

Summary

DTF printing has emerged as a revolutionary solution in the textile industry, offering high-quality prints with easy application that appeals to both commercial and individual users. Its ability to produce vibrant colors and detailed designs sets it apart from traditional printing methods. The versatility of this printing technique allows it to adapt seamlessly to various fabrics, making it an excellent choice for a diverse range of products. Additionally, the cost-effectiveness of DTF printing makes it ideal for small businesses and custom orders, allowing them to maintain profitability without sacrificing quality. With a workflow that is both efficient and user-friendly, DTF printing continues to grow in popularity, offering outstanding opportunities for creativity and commercial success.