In the realm of modern garment printing, DTF Gangsheet Builder Tips stand out as essential insights for maximizing productivity and cost-efficiency. This innovative method of Direct-to-Film (DTF) printing allows multiple design elements to be consolidated on a single sheet, significantly enhancing printing efficiency and reducing waste. Mastering the gangsheet printing technique not only streamlines your process but also ensures a more economical use of materials, making it a preferred choice for savvy businesses. In this article, we’ll explore practical tips that will transform your DTF printing process, giving you the edge in a competitive market. Whether you’re a seasoned printer or just starting in garment printing, these tips will elevate your DTF game to new heights.

Garment printing has experienced a transformation with the introduction of Direct-to-Film methodologies, particularly through the use of gangsheet techniques. These approaches involve the strategic arrangement of various designs on individual film sheets, which provides an efficient way to maximize resource usage while minimizing production costs. With the growing interest in eco-friendly printing practices, understanding how to effectively utilize these gangsheet methods becomes increasingly important for professionals seeking to optimize their production workflows. This exploration will not only simplify the printing process but will also open avenues for creative design possibilities. By leveraging advanced printing techniques, businesses can achieve stunning results with minimal waste.

Understanding the Benefits of DTF Printing

Direct-to-Film (DTF) printing has revolutionized the fabric printing industry by offering a highly efficient method for applying designs to garments. This technology utilizes a process that prints high-quality images onto a special film, which is then heat-pressed onto the fabric. One major benefit of DTF printing is its versatility; it can be used for a wide range of materials, including cotton, polyester, and blends. This flexibility makes it a preferred choice for many garment decorators who need to cater to varying customer preferences.

Another significant advantage of DTF printing is the durability of prints. The designs produced through this method resist fading, cracking, and peeling, ensuring the finished product retains its visual appeal over time. Furthermore, the DTF printing process is relatively straightforward, which allows for quick turnaround times and reduced production costs. Overall, these benefits make DTF an effective solution for both startups and established businesses looking to enhance their garment printing capabilities.

Maximizing Efficiency with Gangsheet Printing

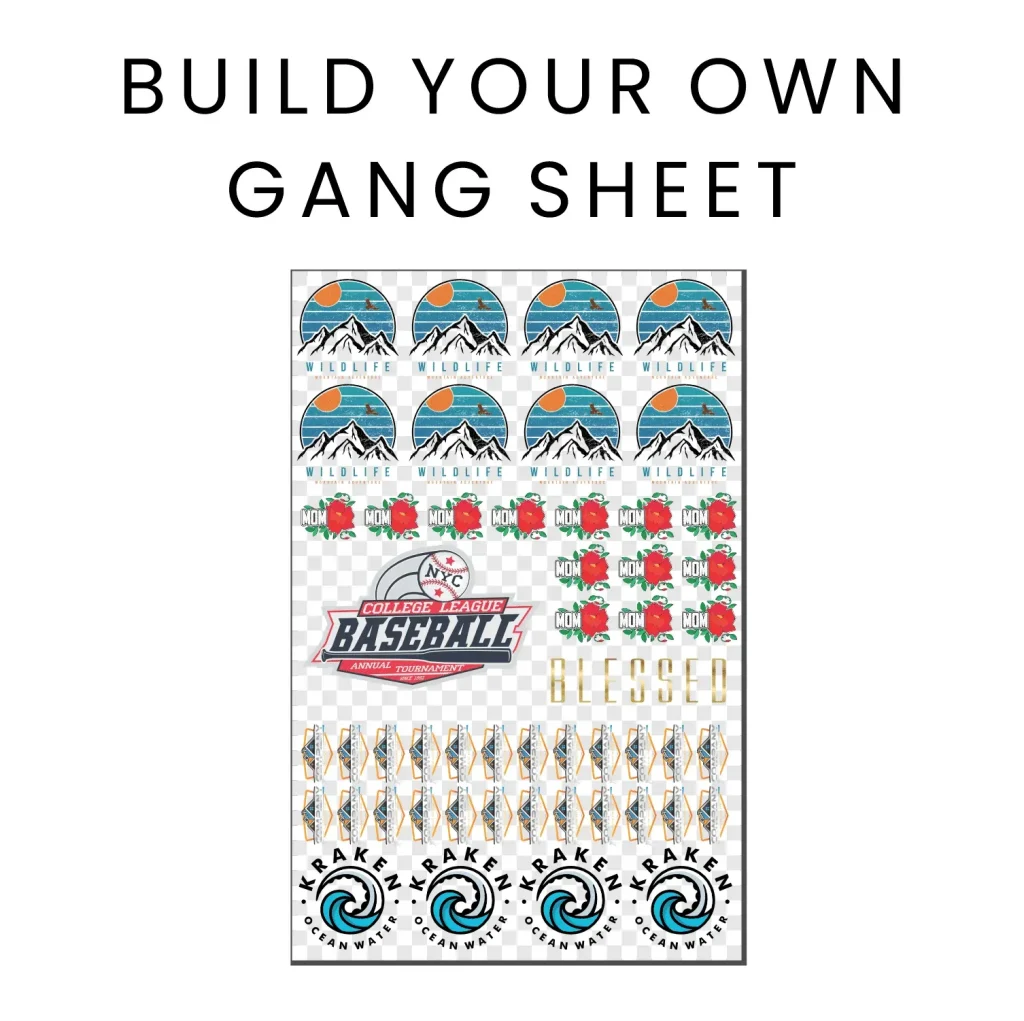

Gangsheet printing is a technique that enhances the efficiency of DTF printing by allowing multiple designs to be printed on a single sheet of film. This method is especially useful for businesses that handle small batch jobs or require variety within a single printing run. By clustering designs strategically, printers can save time and materials, resulting in lower costs per print. Consequently, gangsheet printing increases the overall productivity of the operation, enabling businesses to take on more projects without sacrificing quality.

Additionally, using gangsheet printing can significantly reduce setup times between prints. Rather than switching between multiple print setups for each design, a gangsheet allows printing of several designs simultaneously. This not only optimizes the printing efficiency but also minimizes waste, as the film is fully utilized. By employing effective gangsheet techniques, businesses can streamline their workflow and ensure they meet varying client demands efficiently.

Key Tips for Creating an Effective Gangsheet

When creating a gangsheet, one of the foremost tips is to utilize graphic design software to its fullest potential. Programs like Adobe Illustrator or CorelDRAW provide advanced alignment tools that help in the precise placement of designs on the gangsheet. This strategic arrangement maximizes space, ensuring every inch of film is utilized effectively. Additionally, applying features such as guided grids can aid in the proper alignment and spacing of designs, which is essential for efficient cutting post-printing.

Color management is another critical aspect when it comes to gangsheet creation. Ensuring that your monitor is calibrated properly and utilizing ICC profiles suited to your specific DTF workflow can significantly enhance the color accuracy of prints. Proper color consistency means that the designs printed will closely reflect the intended hues and shades, offering a professional finish that is pleasing to the eye and meets customer expectations.

Selecting Quality Materials for DTF Printing

The quality of materials used in DTF printing greatly impacts the outcome of the final product. Selecting high-quality DTF films and inks is crucial, as they directly influence the vibrancy and longevity of the prints. Investing in premium films ensures that colors pop and maintain integrity during the washing and wearing process. Furthermore, top-quality inks can reduce issues related to fading or discoloration, ultimately leading to higher customer satisfaction and repeat orders.

Moreover, when choosing materials for DTF printing, consider the compatibility of inks with various fabrics and the specific characteristics of the films you use. Some films are designed for specific types of ink and fabric blends, ensuring optimal adherence and durability. By carefully selecting materials tailored to your printing needs, you not only enhance the quality of your output but can also streamline the printing process as a whole, allowing for more efficient operations.

Best Practices for DTF Printing Maintenance

Regular maintenance of your DTF printer is critical to sustaining its performance and ensuring quality output. Implementing a routine cleaning schedule for printer heads and components can prevent clogs and maintain consistent ink flow, which is essential for achieving the best print quality. Additionally, following the manufacturer’s shutdown procedures can help to avoid common ink issues that can arise from improper handling.

Scheduling periodic maintenance checks is also advisable to catch potential problems early on before they disrupt production. Keeping a log of maintenance activities and any encountered issues will aid in tracking the printer’s performance over time, allowing you to make informed decisions about any necessary adjustments or upgrades. By prioritizing the upkeep of your DTF printer, you ensure that your operations run smoothly, reducing downtime and maintaining high-quality output consistently.

Embracing New DTF Printing Technologies

As technology advances, keeping up-to-date with the latest innovations in DTF printing can vastly improve operational efficiency and output quality. Modern DTF printers come equipped with features such as automatic cleaning cycles and predictive maintenance alerts that help to minimize downtime and enhance productivity. These technological advancements not only streamline the workflow but also enable operators to focus more on design and less on equipment issues.

Moreover, investing in the latest printing technology can also open doors for new business opportunities. Upgraded machines often enable wider printing sizes and enhanced capabilities, such as printing on a broader range of materials. By embracing these technological developments, businesses can remain competitive and better serve their clients’ needs, leading to higher satisfaction and growth in the long run.

Frequently Asked Questions

What are the key benefits of using DTF gangsheet printing in garment production?

DTF gangsheet printing maximizes material usage by allowing multiple designs to be printed on a single sheet, significantly reducing waste and printing costs. This method not only improves printing efficiency but also caters to smaller orders effectively, enhancing overall productivity in garment production.

How can graphic design software enhance the DTF gangsheet builder process?

Utilizing graphic design software like Adobe Illustrator or CorelDRAW is crucial for the DTF gangsheet builder process. These applications offer features that enable precise placement, alignment, and arrangement of designs, ensuring optimal use of space and minimizing material waste.

What are some essential tips for aligning designs on a DTF gangsheet for efficient printing?

To align designs efficiently on a DTF gangsheet, use the grid feature in your design software. This tool helps in placing designs accurately, which minimizes wasted space and ensures clean trims after printing, thus enhancing printing efficiency.

How does color management impact the quality of DTF printing results?

Effective color management is vital in DTF printing as it ensures color accuracy and consistency. By calibrating monitors and using appropriate ICC profiles, you can achieve prints that closely match the original designs, preventing issues such as fading and color mismatches in your garments.

What materials are recommended for optimal results in DTF gangsheet printing?

For optimal results in DTF gangsheet printing, select high-quality DTF films and inks. Quality materials ensure vibrant prints and durability, preventing problems like fading and unwanted color outcomes in the final garment, which enhances overall printing quality.

How does routine maintenance improve the efficiency of DTF printing operations?

Routine maintenance is crucial for the efficiency of DTF printing operations. Regular cleaning of printer heads and components prevents clogs, maintains print quality, and helps identify potential issues early, ensuring consistent and smooth printing processes that enhance workflow continuity.

| Key Aspect | Details |

|---|---|

| Introduction | DTF Gangsheet method optimizes material use and reduces costs. |

| What is DTF Printing? | A method that transfers ink from a film onto fabrics, suitable for various applications. |

| Gangsheet Concept | Allows printing multiple designs on one sheet, minimizing waste. |

| Tips for Efficiency | Utilize software, align designs, manage colors, select materials, and use layering techniques. |

| Latest Technologies | User-friendly features like automatic cleaning and predictive maintenance. |

| Maintenance Best Practices | Regular cleaning, follow shutdown procedures, and schedule routine checks. |

Summary

DTF Gangsheet Builder Tips are essential for optimizing your garment printing process. By understanding the significance of gangsheet printing in the DTF technology realm, you can significantly enhance efficiency and reduce costs. Whether you focus on meticulous design alignment, proficient use of graphic software, or maintenance best practices for your printer, each element plays a crucial role in driving productivity. Furthermore, staying updated with the latest advancements in DTF technology will allow you to streamline your operations better. Implementing these tips will ensure that you not only enhance print quality but also maximize your workflow, positioning your business for greater success in the competitive market.