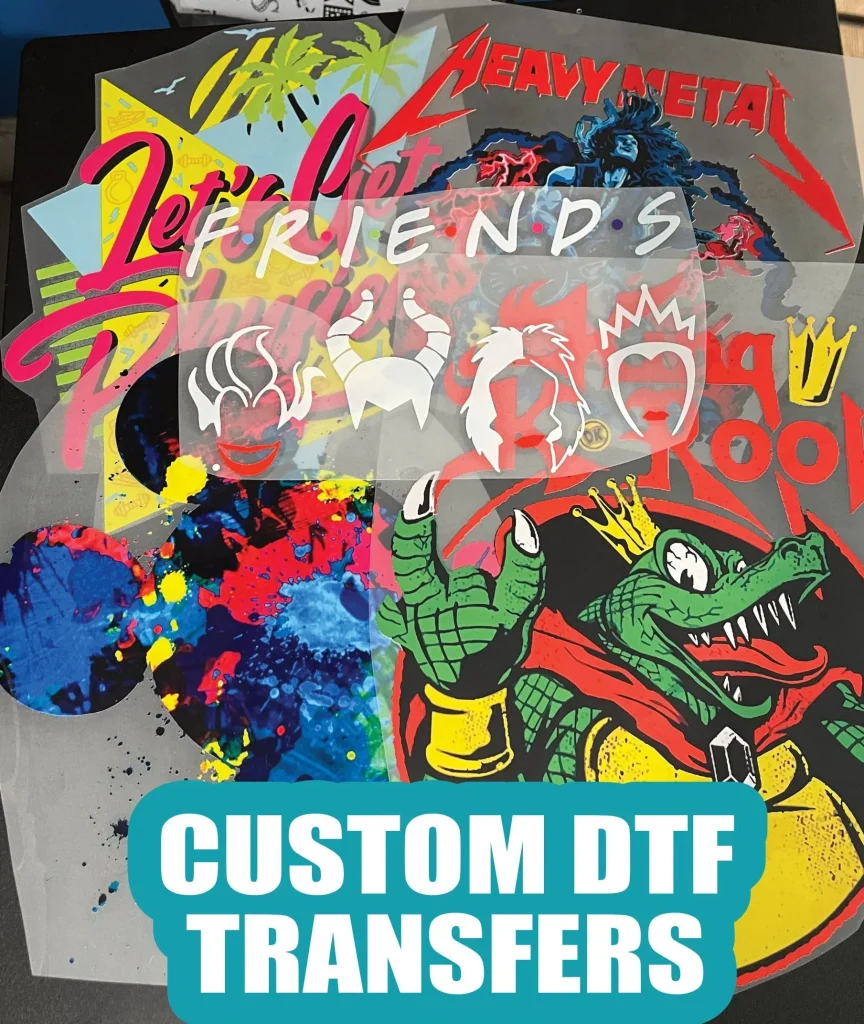

In the dynamic realm of fashion, DTF transfers, or Direct-to-Film transfers, have emerged as a revolutionary technique in custom apparel printing. This innovative printing technology combines vibrancy and durability, allowing for stunning designs that can cater to diverse fabrics, making it a perfect choice for personalized clothing. Unlike traditional methods such as screen printing, DTF transfers empower creators and businesses alike to craft custom shirt designs that resonate with today’s style-conscious consumers. With its ability to produce intricate patterns and vivid colors, DTF printing technology has not only streamlined the printing process but has also fueled a surge in creative expression within the apparel industry. As we explore the impact and potential of DTF transfers, it’s clear that this technology is reshaping the future of personalized apparel.

Direct-to-Film printing, an innovative approach in custom textile printing, offers a fresh perspective on how to create personalized garments. Often referred to as DTF printing, this method enables the transfer of colorful designs onto various fabric types, making it versatile and widely appealing. With advancements in DTF technology, both small businesses and independent artists can engage in custom apparel projects without the limitations of conventional printing techniques. The ability to easily produce high-quality prints means that customer desires for tailored clothing can be met efficiently and cost-effectively. Whether it’s for unique fashion statements or promotional wear, DTF transfers stand at the forefront of modern custom apparel solutions.

Understanding DTF Printing Technology

Direct-to-Film printing technology (DTF) is a groundbreaking method that streamlines the custom apparel printing process. By utilizing a special film coated with a unique adhesive, DTF allows design transfer onto a variety of fabrics, including cotton and polyester blends. The process starts with printing a design onto this film using specialized printers, after which the film is applied to the garment using heat and pressure. This technique ensures that the designs are vibrantly colored and details remain sharp, providing an aesthetically pleasing outcome that appeals to both consumers and creators alike.

One of the standout advantages of DTF printing technology is its flexibility. Unlike conventional printing techniques that may be restricted to specific types of apparel, DTF transfers can be applied to a multitude of garments, including t-shirts, hoodies, and even accessories. This versatility makes it a valuable tool for fashion designers and custom apparel businesses aiming to cater to diverse customer needs. Additionally, DTF printing can produce high-quality products at a fraction of the cost and time compared to traditional printing methods.

Frequently Asked Questions

What are the benefits of using DTF transfers for custom apparel printing?

DTF transfers, or Direct-to-Film transfers, provide several advantages for custom apparel printing, including high-quality, vibrant prints that are durable and resistant to fading. This method is cost-effective, allowing for small batch runs, making it ideal for small businesses. DTF printing is versatile, compatible with various fabrics, and user-friendly, enabling rapid production to meet consumer demand for personalized clothing.

How does DTF printing technology work in creating custom shirt designs?

DTF printing technology works by printing designs onto a special film that is then transferred to fabric using heat and pressure. This process allows for intricate details and vibrant colors in custom shirt designs, enhancing the overall quality and appeal of personalized clothing.

Can DTF transfers be applied to different types of fabrics?

Yes, DTF transfers are highly versatile and can be applied to a wide range of fabrics including cotton, polyester, and their blends. This adaptability makes DTF printing a popular choice for various garments and ensures that businesses can cater to diverse consumer preferences.

Is DTF printing cost-effective for small businesses in the custom apparel market?

Absolutely. DTF printing is cost-effective for small businesses because it allows for lower minimum order quantities compared to traditional printing methods. This means businesses can offer customized options without incurring high upfront costs, making it ideal for startups in the custom apparel market.

What advancements are being made in DTF transfers for customization?

Recent advancements in DTF transfers include innovative solutions that enhance user experience, such as gamification in design processes and intuitive printing technologies. Companies are also introducing more efficient printing equipment, making it easier for both novice users and experienced creators to produce high-quality custom apparel.

What does the future hold for DTF transfers in the custom apparel industry?

The future of DTF transfers in the custom apparel industry looks bright, with ongoing innovations and an increasing number of businesses adopting this technology. The combination of high-quality prints, cost-efficiency, and versatility is expected to drive further growth, as consumers continue to seek out personalized clothing options tailored to their unique styles.

| Key Points | Details |

|---|---|

| What are DTF Transfers? | Direct-to-Film transfers (DTF) are a printing method that prints designs onto a special film before transferring it to fabric, providing vibrant colors and intricate designs. |

| High-Quality Prints | DTF technology produces high-resolution, durable prints that resist fading, ideal for various apparel items. |

| Cost-Effectiveness | DTF transfers allow for smaller orders without high costs associated with traditional printing methods, making it suitable for startups. |

| Versatility in Application | Compatible with a wide range of fabrics like cotton and polyester, offering diverse products for different consumer preferences. |

| Ease of Use | Advancements in technology have made DTF printing user-friendly, allowing even novices to produce high-quality prints. |

| Rapid Production Speed | Shortened production times meet consumer demand for customized products, improving business workflow. |

| Latest Developments | Innovations like gamified customization and more intuitive printing solutions are enhancing user experiences and industry expansion. |

| Future Prospects | DTF transfers are expected to continue driving innovation and growth in the custom apparel market. |

Summary

DTF transfers are quickly becoming a cornerstone in the world of custom apparel printing, transforming how businesses and consumers interact with fashion. The innovation behind DTF technology not only allows for high-quality, cost-efficient, and versatile printing solutions across various fabrics but also simplifies the process for creators and entrepreneurs alike. As more businesses embrace this printing method, the custom apparel landscape is set to thrive, offering unique and personalized clothing options that meet the diverse demands of today’s consumers. DTF transfers stand out not just as a trend, but as a revolutionary advancement that is here to stay, shaping the future of fashion.